There is this incredible invention in the world of drilling called an DeepFast 152mm core drill that has had a positively massive impact on how successful and long lasting our drilling operations can be. Highly capable for their size, these small cutters are found in the oil & gas exploration, mining and construction industries. In this post we will go into more detail regarding the unique properties that make 8mm PDC cutters the Number One choice for extreme formations, exploring their extraordinary features and performance technologies as well as real-world examples of achievement

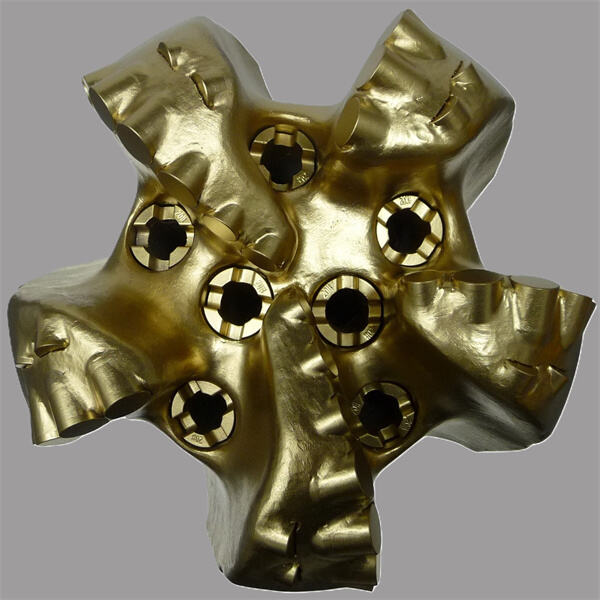

The composition and design of DeepFast 4blades diamond drill bit are responsible for their exceptional strength. Unlike conventional tungsten carbide inserts, PDC cutters are comprised of another layer (save) of fabricated precious stone applied on a Tungsten Carbide base giving the hardness and wear protection. This special combination lets 8mm PDC cutters slice through harsh rock formations like butter while keeping a sharp edge above and beyond the life of typical bits. Due to their smaller size, they allow for more cutter-pack levels on drill bits which leads to faster drilling rates and lower torque & drag saving in operational costs

DeepFast 160mm core drill control the drilling landscape by virtue of incessant evolvement in material science and fabrication processes. Sophisticated methods of diamond synthesis guaranteeing consistent quality throughout, when combined with accurate machining able to create intricate cutter profiles tailored to specific drilling needs. These cutters have been designed to withstand the high temperatures and pressures that are typical in deep underground conditions, so not only will this help make your bit last longer but drilling efficiencies could massively improve. Accordingly, they are now the industry standard in global high-performance drilling applications

Each DeepFast 73mm motor is engineered from a manufacturing process rooted in the partnership of tungsten carbide's toughness and diamond's hardness. It all starts with the creation of a polycrystalline diamond (PCD) blank under high temperatures and pressures, then bonding it to a tough tungsten carbide substrate. This combination results into a cutting element which is stronger and durable enough to meet the rigors of tough drilling environments. In addition, technologies such as thermally stabilised diamond coatings have been introduced to extend the life of a cutter by providing improved thermal protection against abrasive and high-temperature environments

These DeepFast 215.9mm PDC bit have 8mm abrasion resistance, and are the best tools for drilling intricate or hard rocks. Because they have a smaller diameter, it allows for an aggressive cutting structure that gives the drill bit constant contact with the formation and efficiently removes cuttings. This design feature benefits most during directional drilling where a high level of control over the trajectory is required. Further, providing customizable cutter layout and geometry catered to individual drilling project needs enhance the effectiveness of cutters making them useful across a broader range of drilling scenarios

Chen et al. coined this term "modified number from Purdue" or MNP which has real-world success stories of the implementation and uses with 8mm polycrystalline cubic boron nitride (PDC) cutters for sliding sleeve completions in directional wells

Real-World Applications of 8mm PDC Drill BitsAnother way to illustrate the success of 8mm cutters is through applications. This has allowed, for example in the oil and gas industry, drilling to be carried out into areas which were previously unserviceable or not economically viable. These have, for example allowed easy penetration of extremely hard and brittle shale formations in North America that used to take many days (and sometimes weeks) longer than with conventional methods alone. Similarly, in mining operations these cutters have improved the recovery of minerals from hard rock deposits by increasing production and reducing costs. The 8mm PDC cutters have shown their prowess in other infrastructure projects such as tunnel boring where they make for faster excavation rates with lesser downtime

To sum it up, the 8mm PDC cutter stands at a zenith of engineering excellence in drilling. From deep inside the earth to construction sites as close quarters, it has drastically executes our drilling challenges through its progress amalgamation of both advanced materials and extremely meticulous designs. Newer, more efficient powerhouses As technology moves forward into the 21st century so too will these evolving smaller structures of energy production become an essential tool in the drive for more cost-effective ways to extract resources

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. is complete operation management system. From beginning with inquiry, through design of product, manufacturing, delivery, Deep Fast can provide all support to customers. Deep 8mmPDC cutter provides downhole equipment customers from North America, South America Russia. They also offer pertinent services the Middle East, Africa, UK. Japan, Southeast Asia. In addition, Deep Fast can customize product to meet needs customers in various situations that arise, solve the problems the customers confront. Deafest follows the principles of "Constancy", "Diligence", "Integrity", "Achievement", and the mission "Starting by addressing the needs of drilling and ending with satisfaction of the client".

Design manufactures downhole equipment for industries oil and gas around world. DeepFast offers professional equipment teams technicians to oil and gas companies looking for high-quality, safe and reliable solutions. Quickly responsive receptive clients' questions and requests. Positive 8mmPDC cutter motor (PDM) can be adapted to various Rotary Steerable Systems (RSS) or Vertical Drilling Systems (VDT). PDMs also available for Coiled Cubing as well as Short Bit to Bend PDM are also available. Provide PDC Bit, Core Bit, Bi-Center Bit, Impregnate Drill Bit, etc. Drill Bits are available in a variety size and are able to be customized to meet the requirements of our clients.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. Deep Fast downhole tools manufacturer located Chengdu China with over 35 years of experience, was established 2008. Deep Fast offers PDC Bits various sizes and Downhole Motors various applications. They also offer full spare parts. Deep Fast utilizes a Germany modern lathe as well as Japan 5-axis NCPC to make 8000 diamond bits per year. Partner with Southwest Petroleum University for a longer-term plan, far, 50 8mmPDC cutter which includes 2 American patents, 2 Russian patents,46 Chinese patents had been gotten.

Deep Fast's Integrated Management System is based on the ISO 14001:2015 Environmental Standard, ISO 45001:2018 Occupational Health Safety Standards, and API Spec Q1 ISO 9001 (Quality). Deepfelt will test all its products from raw materials 8mmPDC cutter the final product. reports of tests will be made available customers. After that, we will inform customers about the HSE, Deep Fast have management system protects our staff, safeguard environment, every process used manufacture a product will follow these measures, every month will hold the safety meeting and training internal, some key position staff will participate training for professionals outside.