The kind of cutting oil that you utilize can have a major influence when it comes to doing drilling work. Not only does this save you time and money, it also helps in prolonging the life of your drill bits. There are now tons of cutting oil in the market which makes it difficult for you to choose one.

To clear things up and to help you make an informed decision, we delve deep into everything that relates to choosing the best cutting oil for drill bits by presenting a comprehensive guide. In this article, we will examine the best 5 cutting oils that are commonly used for drill bits, methods to prolong your drill bits life with the correct cutting oil, what benefits can you get by using high-qualitycutting oil in drilling operations and comprehensive knowledge on how to effectively apply cutting oil to yourdrillbits.

Mineral Oil - a well-known one and budget-friendly solution, good for the most common kind of drilling. Please note that it will leave a white residue on your workpiece and you might see this visible after finishing.

Vegetable Oil: A biodegradable and good lubricant alternative to mineral oil. However, it might not be the best choice for drilling applications that require high-speeds.

Synthetic Oil - this type of oil is ideal for high-performance, fast drilling and Advantages include its superior lubricating quality as well as the ability to hold up in extreme temperatures. Although its incredible effectiveness, businesses that manufacture synthetic oils might charge a lot more than what you would expect from another product.

Semi-Synthetic Oil: Combining the benefits of mineral and synthetic oils, semi-synthetic oil is a better option for drill bits. Moreover, semi-synthetic is a cheaper alternative to synthetic oil; however, its applicability to all drilling cases is also questionable. Cutting Oil with EP Additives : This type of oil has EP additives, which provide better protection against wear and tear while drilling harder materials, such as stainless steel and titanium. Strategies for making your drill bits last longer: Finding the right cutting oil is the beginning of conserving your drill bits. Here are a few measures to back up this claim: Optimal Speed Usage: Sticking to your drill bit’s recommended speed band can significantly improve its lifespan Correct Feed Rate: Do not let your drill bit get too hot; rather, keep the feed rate within the suggested boundaries Regular Maintenance: Keep your drill bits clean by clearing them of any accumulated substances or wastes that could harm their efficiency Utilize a Sharpening Jig: Bring back them to life by using a sharpening jig on your duller drill bits. Advantages for better quality cutting oil for drill bits: High-quality cutting oil offers a variety of advantages, including the following: Enhanced Longevity: Cutting oil may significantly extend the life of your drill bits by decreasing wear and tear Improved Performance: This can help you optimize the efficiency and precision of your drilling operations Cost-Efficiency: Fewer drill bit replacements equate to long-term cost savings Enhanced Workpiece Finish: Improve the final finish of your piece by reducing the amount of heat generated during the drilling process

You have now discovered the perfect cutting oil for your drill bits, but how do you apply it exactly. Some other recommended practices include:

Deep Fast's Integrated Management System is based on ISO 14001:2015's Environmental Standard, ISO 45001:2018 Occupational Health and Safety Standards, as well as API Spec Q1 ISO 9001 (Quality). From the raw materials through the final product, deep fast will take strictly test measures ensure quality of their products, the results of tests will be made available to customers. Also, relation the HSE, Deep Fast have safety cutting oil for drill bits place protect employees, as well as protect our environment, every manufacturing procedure will follow these measures Every month, we hold safety meetings training internal, some employees in key positions will take part in training for professionals outside.

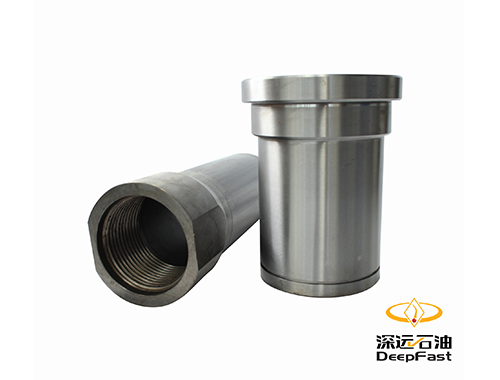

Design manufacture downhole tools oil and gas industries all over world. Deep Fast employs highly skilled equipment as well as technical teams serve the oil gas industry who are looking secure, efficient, secure solutions. Rapidly responsive and open to customers' concerns and requests. Positive displacement cutting oil for drill bits (PDM) adaptable to different Rotary Steerable Systems (RSS) or Vertical Drilling Systems (VDT). Additionally, manufacture the Short Bit to Bent PDM, in addition to, PDM Coiled Cubing is available. Provide PDC Bits, Core Bits, Bi-Center Bits, Impregnate Bit, etc. Drill Bits are available a variety size and are able to be customized to meet requirements of our customers.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. is complete operation management system. From beginning with inquiry, through design of product, manufacturing, delivery, Deep Fast can provide all support to customers. Deep cutting oil for drill bits provides downhole equipment customers from North America, South America Russia. They also offer pertinent services the Middle East, Africa, UK. Japan, Southeast Asia. In addition, Deep Fast can customize product to meet needs customers in various situations that arise, solve the problems the customers confront. Deafest follows the principles of "Constancy", "Diligence", "Integrity", "Achievement", and the mission "Starting by addressing the needs of drilling and ending with satisfaction of the client".

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. founded in 2008, with more than 35 years' experience downhole tools, located Chengdu, China, Deep Fast can provide PDC Bits various sizes, Downhole Motor used different operation situation, complete cutting oil for drill bits parts can be used support equipment. Deep Fast uses Germany modern lathe and Japan 5-axis NCPC to make 8000 diamond bits each year. Collaborate with Southwest Petroleum University for long-term plan. As now, 50 patents including 2 American patents, 2 Russian patents, 46 Chinese patents were obtained.