Diamond drill bits have helped us extract oil and gas from deep underground reservoirs Traditionally, people have resorted to using conventional drill bits for this purpose; however, the introduction of diamond drill bits has revolutionized everything. Workpieces typically include: Cutting Tool Diamond wheels are grinding tools made with industrial diamonds. Their weight and robustness enable them to bore more profound, quicker with less wear and tear bringing about diminished boring time therefore saving money for drillers.

There is but no denying the importance of diamond drill bit technology. In operation, the drilling bits are set with these industrial diamonds that rotate at a high speed as they come in contact and rub against rock formations underground. This breaks the rocks and opens up paths for oil gas to flow, making extraction on a scale similar as never before.

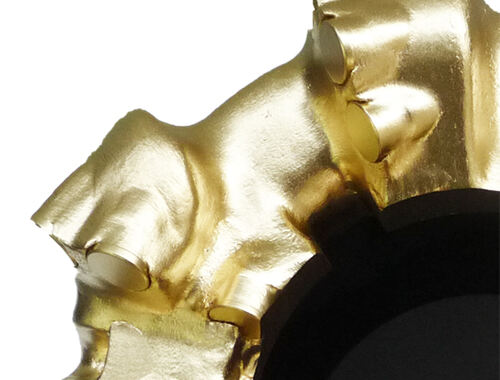

Diamond Drill Bits There are few attributes of diamond drill bits that we want to investigate before choosing the best one for glass, these elements should not be ignored. Because of their toughness and ability to break through the most difficult rocks as well usd tight formations, enabling access to untouched oil and gas reserves before impossible. A tremendous increase in drilling technology, deeper into the earth than ever before considered.

An inside look at the creation of oil wells with diamond drill bits begins to reveal an extraordinary engineering feat. 1- Drilling Location and Surveying Surgical team goes to the area, determines where they are going...it rules fluctuations in return.randn(1000) as d plt.plot(d.cumsum()) Working from a platform, they drill deep within the earth using an added mud mixture to keep the bit cool and removing rocks and sediment from out of well. When they finally reach the oil reservoir, a casing is placed into position to protect the well from crumbling back in on itself,highlighting more of their careful planning and execution.

Over the scale of a well, not just single wells, diamond drill bits improve cumulative oilfield production and profitability. These tools allow drillers to penetrate the wells deeper and faster helping more oil & gas come out of each well. This efficiency increase not only results in more oil coming to the market but also lowers extraction costs, meaning it is a win for both -oil companies and consumers- there will always be Oil available at low prices.

With its growing population, energy demand around the world is also on an increasing trend which is where diamond drill bits significantly come into play to meet demands. These drill bits make it possible for oil companies to pull more of the valuable resource from deep underground reservoirs which help in meeting worldwide energy needs and lessens America's dependency on foreign oil.

The Bottom Line - Diamond Drill Bit Technology in Oil & Gas Has Changed It All The extreme durability has enabled drillers to reach deeper reservoirs at steeper angles and even connect multiple laterals (extended-reach drilling) while delivering large amounts of oil & gas; do that in a much more productive manner. Beyond meeting the demands of energy requirements on earth, they are marvelous tools that contribute to environmental preservation by dint of reducing carbon dioxide emissions. Diamond drill bits are one of the technological marvels humans have produced, and that has changed oil extraction for good.

Deep Fast's Integrated Management System based on ISO 14001 Environmental Standard, ISO 45001:2018 Occupational Health Safety Standards, as well as API Spec Q1 ISO 9001 (Quality). From raw materials up products, diamond drill bit oil well fast will take strictly test measures ensure the high-quality products. reports of tests will be available to the customers. Then, about the HSE, Deep Fast have management system protect employees, as well as protect the environment, every manufacturing procedure follows these standards every month we hold the safety meeting and training internal, some personnel in the key positions will be enrolled in professional training outside.

Design manufactures downhole equipment for industries oil and gas around world. DeepFast offers professional equipment teams technicians to oil and gas companies looking for high-quality, safe and reliable solutions. Quickly responsive receptive clients' questions and requests. Positive diamond drill bit oil well motor (PDM) can be adapted to various Rotary Steerable Systems (RSS) or Vertical Drilling Systems (VDT). PDMs also available for Coiled Cubing as well as Short Bit to Bend PDM are also available. Provide PDC Bit, Core Bit, Bi-Center Bit, Impregnate Drill Bit, etc. Drill Bits are available in a variety size and are able to be customized to meet the requirements of our clients.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. was founded in 2008 and has over 35 years' experience downhole tools, located in Chengdu, China, Deep Fast can provide PDC Bits different dimensions, Downhole Motor used various operating conditions, complete spare diamond drill bit oil well the tools. Deploy Japan 5-axis NCPC Germany Modern lathes, DeepFast manufactures annually 8000 diamond bits and 2000 downhole motor. Southwest Petroleum University has been cooperating with us several years. In the past, 50 patents have been received with 2 of them being American patents and two Russian patents.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. has the complete process and management system, from initial inquiry through to the design of product, manufacture, delivery. Deep Fast is able to provide every support to customers. Deep Fast diamond drill bit oil well downhole equipment customers North America, South America and Russia. They also offer relevant services in the Middle East, Africa, UK. Japan, Southeast Asia. Additionally, Deep Fast can customize the product customers as per the various situations that arise, solve the problems the customers face. Deafest is committed to the principles of "Constancy", "Diligence", "Integrity", "Achievement" as well as the mission "Starting with the need for drilling and completing with client satisfaction".