The Wonderful Planet of Oil Rigs and Diamond Drill Bits: Ever seen an oil rig? An oil rig is a huge machine! The mast is a massive steel beam [that] reaches up to the heavens, and it's mounted on enormous wheels. At the very end of this machine there is a drill bit that goes way up and down directly into the ground. Before I tell you what The Rig is all about, for those of you who have not seen an oil rig before; these little (being ironic) machines play a massive part in our everyday life. They are what help us get millions and billions of barrels, which is a type energy resource on landscapes known as fossil fuel. This fuel is then burned to power our cars and warm our houses. On top of that, there are a huge mass or products we consume in our day-to-day life made from such fuel like plastic items or other materials.

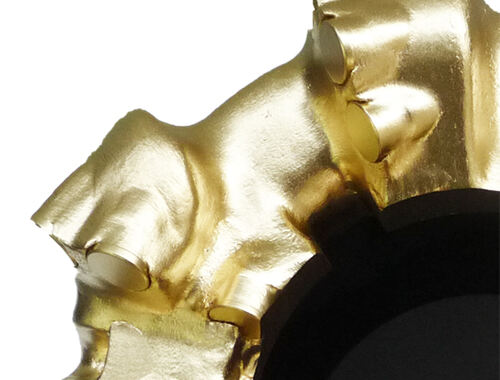

The drill bit is one of the most fascinating pieces on an oil rig and you may have seen it before, as often it’s covered in diamonds. These drill bits have diamond-tipped edges that are so tough they allow the machines to do their job in difficult rock and soil. These DeepFast diamond core drill are what makes these drill bits possible and have the ability to cut through materials that would be too hard for regular wood or metal drilling bit. Taking a closer look into the world of diamond drill bits, and see how they play an important role in aiding oil rigs to function more effectively.

Diamond tip drill bits are extremely durable specialized drilling equipment. Diamond is one of the hardest material on Earth that's why it can drill into thick rock and dense earth. Think of these DeepFast Drill Bits as little jackhammers that chop through earth to help oil and gas escape. This is important as the sooner we can reach its oil in that part - the rest of process becomes efficient.

It is important to emphasize that it costs more than just a raw piece of diamond on the end of metal tube. DeepFast combined drilling are designed with meticulous attention to detail and precision styling fit for the job. And that calls for a lot of time and brainstorming on the best working performance.

Oil rigs are dangerous work areas that operate under high pressure. Engineers and scientists from the field of oil industry are not lagging with safety. So they are always innovating and trying to create new better as well safer protective equipment for workers. That is that they are constantly being worked towards, the newest objects among oil rig safety equipment - designs and technologies.

For one thing, the use of diamond tip drill bits means that gas-line companies can get their job done a lot faster, an advantage for them but also (as I pointed out) good news in terms of safety. The DeepFast diamond core drill bit faster that drilling can be completed, fewer risks there are for the workers doing it - making everybody happier. That also saves costs during the drilling, which is a major point of interest for an oil and gas company. A declining cost also tends to mean energy can be distributed cheaper to people and business.

Diamond drill bits have evolved over the past 50 years and they are not simple tools at all. These DeepFast diamond core bit are fascinating to make. Nonetheless, what happens is the exclusive diamond stones are gathered from around many locations and they get washed out in factories being categorized. Individual diamonds are then put on the drill bit and locked into a metal holder. The bits are then put through a series of tough tests makes sure that they all perform well and meet safety requirements.

Its production method is very detailed and meticulous, that describes the reliability of diamond drill bits to be true. Every bit is rigorously tested by its group of engineers and scientists to ensure that it can withstand the harsh environment in drilling.

It has to be mentioned that diamond drill bits are pretty useful things, but on the other side -scientists and engineers always looking for some better way. Now, the technology is helping them learn how drill bits actually perform in different settings. For instance, they can run digital modeling that shows what attributes impact drilling performance. This lets them produce more efficient real-world field tools that are specifically tuned for different types of rock and geological settings.

Advances in technology and drill bit design mean that diamond is better-equipped to last longer while performing more effectively, leaving everyone in the oil gas industry feeling like a winner.

Design manufacture downhole instruments the oil and gas industry around globe. Deep Fast utilizes professional equipment technical teams service oil gas industry looking safe, efficient, reliable solutions. Quickly responsive and receptive clients' questions and demands. Positive Displacement Motor (PDM) adapts various Rotary Steerable Systems (RSS) and Vertical Drilling System (VDT). Additionally, they manufacture the Short Bit Bent PDM, additionally, PDM for Coiled Cubing offered. They offer PDC Bit, Core Bit and Impregnate Bit, etc,. with different sizes, also can customize the Drill Bits Diamond drill bits for oil rigs to the requirements of customers.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. established 2008 and has more than 35 years' experience downhole equipment, based Chengdu, China, Deep Fast can supply PDC bits various sizes, Downhole Motor used various operating conditions, and complete spare parts the Diamond drill bits for oil rigs. Deep Fast makes use Germany modern lathes as well Japan 5-axis NCPC manufacture 8000 diamond bits every year. Cooperate with Southwest Petroleum University for long term, as far,50 patents, which include 2 American patents,2 Russian patents, 46 Chinese patents have been obtained.

Deep Fast has created an Integrated Management System that follows the standards API Spec Q1 ISO 9001:2015 (Quality), ISO 45001:2018 (Occupational Health and Safety), ISO 14001:2015 (Environmental). Deep fast will test every product from raw Diamond drill bits for oil rigs final product. results these tests will be provided to the customers. After that, will inform customers about HSE, Deep Fast have security system in place safeguard employees' company, and ensure the protection of our environment, each process used to manufacture product will follow these measures Every month, we will hold the safety meeting and internal training, while some key position staff will participate in professional training outside.

Deep Fast Oil Drilling Tools., Ltd. is able to provide all products and services to customers. From the initial inquiry through design the product, to manufacturing, to the delivery the product, Deep Fast has complete management system. Deep Fast provides downhole tools customers from North America, South America and Russia. They also provide relevant services in Middle East, Africa, UK. Japan, Southeast Asia. Deep Fast is also able customize its products to meet the needs of the customer depending on the particular circumstances they confront. Diamond drill bits for oil rigs always stuck to its core values of "Constancy and Integrity, Determination Success" and the goal of "Starting from the drilling requirements and ending with satisfaction from clients".