Want to know more about directional drilling motors? Holes are drilled into the ground using these impressive machines, and they can be very handy for a plethora of projects. Today we will discuss some of what directional drilling motors are, how they work and also their importance.

Directional drilling motors are a separate class of equipment that is used in the process of wellbore boring, but according to another principle. These motors drill horizontally, laterally or at an angle instead of going straight down. This ability can be especially helpful for certain drilling projects. An example of this is when you are faced with the need to drill under a road, there directional drilling motor can be used in order for ones not having to eliminate the obstruction.

Additionally, these motors come with the benefit of being both cost-effective and time-saving. Traditional drilling will often require significant time/investment to dig through earth until arriving at the desired drill location. Nonetheless, with a directional drilling motor, you can drill from afar by avoiding extensive excavation.

Certainly, drilling is one of the most appropriate areas where directional motors prove as a complete solution for any possible drilling in tough remote sites. This makes them the perfect choice for drilling in places that are too far away or which cannot be reached by conventional means. ConclusionOn a conclusion note, if your drilling is located in an isolated setting or something similar where you have to lay the drill on it then using one of these directional drilling motor can greatly help with this without having to set down those additional heavy machinery.

The Power and Utility of Directional Drilling Motors

Directional drilling motors are powerful machines capable of cutting through the toughest material. And designed to work through all type od soil compositions from soft clay to solid rock formations, These motors ensure that the well gets drilled no matter what. This is due to their high strength and ease of operation, promoting user confidence across different drilling environments.

Aug 6, 2018 | By Compass Drilling Auger Bits, Continuous Flight AugersHow A Directional Drilling Motor Can Add Value In Addition To Productivity Furthermore Read More Taghow D --By admin44 Comments

Among the many ways that a directional drilling motor can be more efficient and therefore save costs are: For one, by allowing drilling from an infield well pad design -- which eliminates the need for significant ground excavation (which cuts down on site prep time and costs. Secondly, the impressive power of these motors directly contributes to faster project completion in comparison with conventional devices. Finally, with less need for heavy machinery transportation the transport costs are lower.

The right directional drilling motor will be the difference between hitting a target or missing it. From sandy to clay soils, there are many options available on the market that cater for your project. The best labeler for you depends on the type of terrain where your motor will unwind; some motors perform better in loosened dirt, while others were made to sheer through rock. Differences in power levels also make a difference as well, especially when they face challenging drilling situations.

There are things to take into consideration when deciding which earth auger is right for you, including your ground type, drilling depth and budget. Choosing the proper directional drilling motor can help your project advance quickly, successfully and without exceeding budget.

To sum it all up, the drilling motors are a great piece that can really improve just about any kind of project out there. Whether you are drilling in a remote placement, navigating obstacles such as roads or challenging the soil wire-framing so full of a directional drilling motor is optimal for it all. Understanding the benefits of these motors, respecting their power and useful life takes you one step further to ensure your next drilling project is a success.

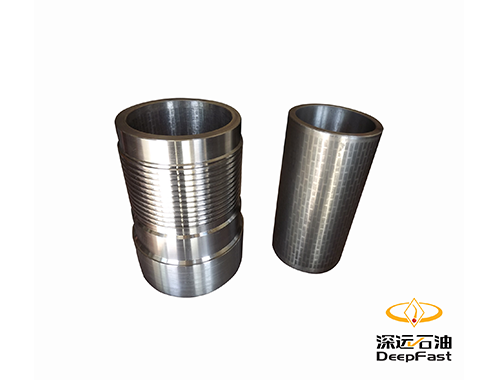

Create manufacture downhole tools used by the companies the oil and gas industry across world. Deep Fast employs highly skilled equipment and technical teams service the oil gas industries looking for safe, efficient, secure solutions. Fastly responsive to customers' concerns as well as requests. Positive Displacement Motor (PDM) is able to adapt to different Rotary Steerable System (RSS) Vertical Drilling System (VDT). PDMs are also available for Coiled Cubing as well as Short Bit to Bend PDM are also available. PDC Bits, Core Bits, Bi-Center Bits directional drilling motor Drill bits, more. readily available. Drill Bits are available in a variety of sizes and can be designed to meet the requirements of our clients.

Deep Fast's Integrated Management System is based ISO 14001:2015's Environmental Standard, ISO 45001:2018 Occupational Health Safety Standards, as well as API Spec Q1 ISO 9001 (Quality). From raw materials products, deep fast will take strictly test measures ensure the quality their products, results tests will be provided to customers. Then, about the HSE, Deep Fast have directional drilling motor system to protect employees and ensure protection of our environment, each manufacturing procedure be governed by these rules, every month hold the safety meetings and internal training, while some important employees will be involved in professional training outside.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. was founded in 2008 and has over 35 years' experience downhole tools, located in Chengdu, China, Deep Fast can provide PDC Bits different dimensions, Downhole Motor used various operating conditions, complete spare directional drilling motor the tools. Deploy Japan 5-axis NCPC Germany Modern lathes, DeepFast manufactures annually 8000 diamond bits and 2000 downhole motor. Southwest Petroleum University has been cooperating with us several years. In the past, 50 patents have been received with 2 of them being American patents and two Russian patents.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. has the complete process and management system, from initial inquiry through to the design of product, manufacture, delivery. Deep Fast is able to provide every support to customers. Deep Fast directional drilling motor downhole equipment customers North America, South America and Russia. They also offer relevant services in the Middle East, Africa, UK. Japan, Southeast Asia. Additionally, Deep Fast can customize the product customers as per the various situations that arise, solve the problems the customers face. Deafest is committed to the principles of "Constancy", "Diligence", "Integrity", "Achievement" as well as the mission "Starting with the need for drilling and completing with client satisfaction".