Drill equipment at your service helps designing a holes drive for materials Wood or metals. There are different types of drilling equipment like hand drills, power drills and drill presses. The way that they work is that a tool will turn and spin the drill bit, which in itself is a metal attachment shaped similar to either one of these two shapes: cone or blister.

Choosing the Right Drill Equipment for Your Needs Before using a drill, it is important to determine what you will be drilling. Are you looking for a portable option that is small enough to take on the road, but probably not powerful enough in general? Things to Keep in Mind when Setting it UpThe key consideration is: Consider the power (in volts) as well dimensions of both, size and battery life; DO IT RIGHT!!

Drilling equipment is an essential part of many industries, from oil and gas exploration to mining and construction. This specialized equipment is designed to drill into the earth or other materials in order to extract valuable resources or create holes for various purposes. The technology behind drilling equipment has evolved significantly over time, improving efficiency and safety on job sites.

In the past, drilling was often done using manual labor or basic mechanical tools. Today, however, the use of more advanced equipment has made drilling faster, safer, and more efficient. Modern drill equipment is typically powered by electricity, hydraulics, or air pressure, allowing for greater precision and control. This equipment ranges from small, hand-held drills to massive rigs that can reach depths of several kilometers.

One of the key advantages of modern drilling equipment is its versatility. This equipment can be used for a wide range of tasks, from drilling shallow water wells to extracting oil and gas from deep beneath the Earth's surface. Some types of drill equipment are even designed for use in space exploration or other extreme environments. This versatility allows industries to adapt and evolve, meeting the changing demands of their customers and the world around them.

Of course, with any type of equipment, safety is always a top priority. Drill equipment is no exception, and manufacturers have taken great strides to improve safety features and reduce the risk of accidents. Modern drill equipment is designed with safety in mind, including features such as automatic shut-offs, emergency stop buttons, and safety guards. These measures help to protect both workers and the environment in which they operate.

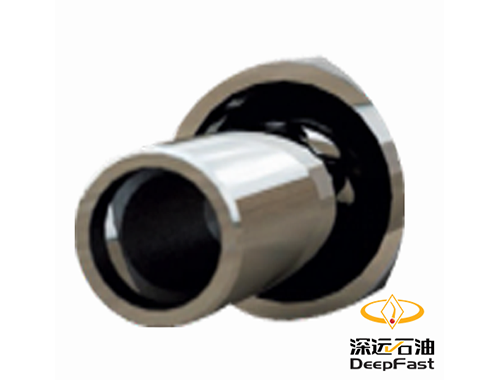

Design manufacture downhole instruments the oil and gas industry around globe. Deep Fast utilizes professional equipment technical teams service oil gas industry looking safe, efficient, reliable solutions. Quickly responsive and receptive clients' questions and demands. Positive Displacement Motor (PDM) adapts various Rotary Steerable Systems (RSS) and Vertical Drilling System (VDT). Additionally, they manufacture the Short Bit Bent PDM, additionally, PDM for Coiled Cubing offered. They offer PDC Bit, Core Bit and Impregnate Bit, etc,. with different sizes, also can customize the Drill Bits drill equipment to the requirements of customers.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. established 2008 has more than 35 years of experience with downhole tools. Located Chengdu, China, Deep Fast provides PDC Bits in different sizes, Downhole Motor used different operation situation, complete spare parts support the products. Install Japan 5-axis NCPC and Germany Modern lathe, Deep Fast produces annually an average of 8000 diamond bits, 2000 downhole motors. Work with drill equipment Petroleum University for a longer-term plan, so far, 50 patents that includes 2 American patents,2 Russian patents, 46 Chinese patents have been granted.

Deep Fast Oil Drilling Tools Co., Ltd. offers all kinds of services its clients. From the initial inquiry the design of product, through manufacturing, and finally delivery of product, Deep Fast has a complete management system. Deep Fast supplies downhole equipment related services to clients across North America, South America, Russia, Middle East, Africa, UK, Japan, Southeast Asia. Deep Fast will also modify the product meet drill equipment of the customer depending on the particular circumstances that they facing. Deafest has always stuck principles of "Constancy and Integrity, Determination and Achievement" and the goal "Starting at the beginning drilling needs and ending with complete satisfaction by clients".

Deep Fast's Integrated Management System is based on the ISO 14001:2015 Environmental Standard, ISO 45001:2018 Occupational Health Safety Standards, and API Spec Q1 ISO 9001 (Quality). Deepfelt will test all its products from raw materials drill equipment the final product. reports of tests will be made available customers. After that, we will inform customers about the HSE, Deep Fast have management system protects our staff, safeguard environment, every process used manufacture a product will follow these measures, every month will hold the safety meeting and training internal, some key position staff will participate training for professionals outside.