Mining for oil and gas is serious business that intends to be done correctly, therefore apart from DeepFast diamond core drilling pieces were very primitive and usually made of heavy metals like steel or iron. These fundamental bits, while good for their day, were not always the easie, also other equipment used in the mining industry. In addition, an increasing number of companies is currently applying sensors to study their drilling operations.

The first bits were as basic tools made from wooden, metal or stone. These set of DeepFast diamond core drilling pieces were very primitive and usually made of heavy metals like steel or iron. These fundamental bits, while good for their day, were not always the easiest or most efficient to use.

Modern companies, meanwhile, have begun employing 3D printing to manufacture bespoke drill bits for varying rock and soil types. That means instead of being a one-size-fits-all solution, companies create DeepFast diamond core drilling that makes them drill quicker and more effectively, which yields better results.

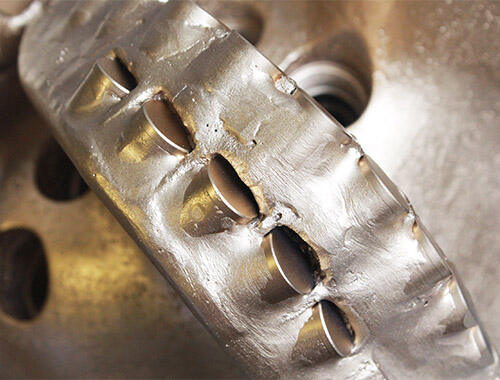

When you drill for oil and gas, choosing the right drilling bit is crucial. There are DeepFast core drilling bits for rocks and also different depths in which you can drill. A PDC bit, for instance, is good at drilling through soft rocks where a tricone bit might be the better choice if you were going through harder rock formations.

In oil and gas drilling, safety is always the first. Some of the problems that may arise include excessive heating and vibration, which can ultimately result in costly workmanship faults or outright accidents. Workers use coolants and special drill bits like DeepFast diamond core drilling to ensure drilling holes does not overheat anything.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. is complete operation management system. From beginning with inquiry, through design of product, manufacturing, delivery, Deep Fast can provide all support to customers. Deep Drilling bits oil and gas provides downhole equipment customers from North America, South America Russia. They also offer pertinent services the Middle East, Africa, UK. Japan, Southeast Asia. In addition, Deep Fast can customize product to meet needs customers in various situations that arise, solve the problems the customers confront. Deafest follows the principles of "Constancy", "Diligence", "Integrity", "Achievement", and the mission "Starting by addressing the needs of drilling and ending with satisfaction of the client".

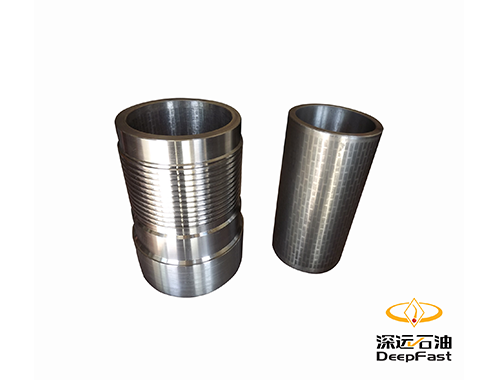

Create manufacture downhole tools to serve the oil gas industries across the globe. Deep Fast provides professional equipment and technicians to companies in the oil and gas industry looking for safe, efficient and reliable solutions. Rapid response and responsiveness client's questions and requests. Positive Displacement Motor (PDM) can be adapted to various Rotary Steerable Systems (RSS) Drilling bits oil and gas Drilling System (VDT). Also manufacture the Short Bit to Bent PDM, additionally, PDM for Coiled Cubing is provided. Provide PDC Bit, Core Bit, Bi-Center Bit, Impregnate Drill Bit, etc,. Drill Bits available in a variety of sizes and are able be designed meet the requirements of our clients.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. Deep Fast downhole tools manufacturer located Chengdu China with over 35 years of experience, was established 2008. Deep Fast offers PDC Bits various sizes and Downhole Motors various applications. They also offer full spare parts. Deep Fast utilizes a Germany modern lathe as well as Japan 5-axis NCPC to make 8000 diamond bits per year. Partner with Southwest Petroleum University for a longer-term plan, far, 50 Drilling bits oil and gas which includes 2 American patents, 2 Russian patents,46 Chinese patents had been gotten.

Deep Fast's Integrated Management System based on ISO 14001 Environmental Standard, ISO 45001:2018 Occupational Health Safety Standards, as well as API Spec Q1 ISO 9001 (Quality). From raw materials up products, Drilling bits oil and gas fast will take strictly test measures ensure the high-quality products. reports of tests will be available to the customers. Then, about the HSE, Deep Fast have management system protect employees, as well as protect the environment, every manufacturing procedure follows these standards every month we hold the safety meeting and training internal, some personnel in the key positions will be enrolled in professional training outside.

Technology is continuing to push the future possibilities of drilling bits. Today, our top DeepFast combined drilling rigs can even work autonomously processing live data to guide intelligent step by steps moves. This level of automation could further improve drilling efficiency and safety.