Downhole tools are some of the most important pieces in helping workers to extract oil and gas from miles beneath our feet. A key component of this is well construction, which includes tools and equipment that ensure safe and efficient drilling. In this post, we will be digging deeper into the latest tools and discovering how these modern helping hands are of real benefit to both workers as well as worksite itself. This doesn't often come across to mean guides, but more so the parts that play into how easily we can derive these commodities; and why knowing what they are is important.

Downhole tools are much improved and efficient now due to the advent of new technology. This revolutionary technology helps the drilling companies to reach their oil and gas resources much faster and precisely. Many types of downhole tools such as drill bits, pumps, motors and sensors are used. All these tools have a specific role in making the drilling process easier. Drill bits break through hard rock, pumps and motors get the drill moving and extract resources. Why are these crucial - it helps in drilling faster and captures important data, one can leverage to better the process even more.

Downhole tools - These can help to increase the pace of drilling greatly. For example, certain drill bits have unique diamond coatings that make it easier for them to dig through rock. As a result, they do not need to be replaced as frequently; saving time and money. In other words, pumps and motors are designed to move more fluid when drilling faster. The wireline must also be equipped with important tools like the sensor that collects valuable information about the well such as temperature and pressure. It enables companies to adapt their work for the oncoming future more efficiently and saves them precious time during drilling.

In order to drill more drilled holes, it is important that the drilling operation be as accurate as possible and one way of achieving this with precision tools. A tricone bit is one of the more essential pieces in a precision tool kit. This original gadget has 3 cones that revolve at differing speeds This allows the drill to safely navigate different types of rock and sediment. Another weapon in his arsenal is the gyroscopic sensor It is this tool that helps to the extent of securing, and not allowing the masonry drill bit stray from its lane. In terms of operations, drilling more efficient holes automatically improves the results with reduced waste, which is critical for safe and effective operation.

Downhole tools can also prevent issues and save time for oil drilling companies. This detailed information is important for the companies to monitor the well. For instance, sensors scrap information regarding the temperature and pressure of the well. This gives the companies a tight control over what goes in because they can keep an eye on that well and prevent problems before it even happens. The company saves itself the precious time and resources that would have had to go into correcting an issue down the road by early detection 4. By being proactive, drilling operations can go more smoothly overall.

Some of the most important facets downhole tools have to offer are related directly to worker safety and they help reduce some strains that come along with working in this industry. A BOP is equipped with safety valves that can prevent blowouts from occurring. Blowouts are life-threatening scenarios that can cause equipment malfunctions and even ignite fires, thus endangering employee lives. Moreover, sensors have a key function in scanning the well for alarms to warn of potential dangers before they become catastrophic. There are a variety of additional tools readily available that can help reduce the likelihood of accidents, making workers more secure while they operate in various oil fields which may not have hard hats or other such precautions.

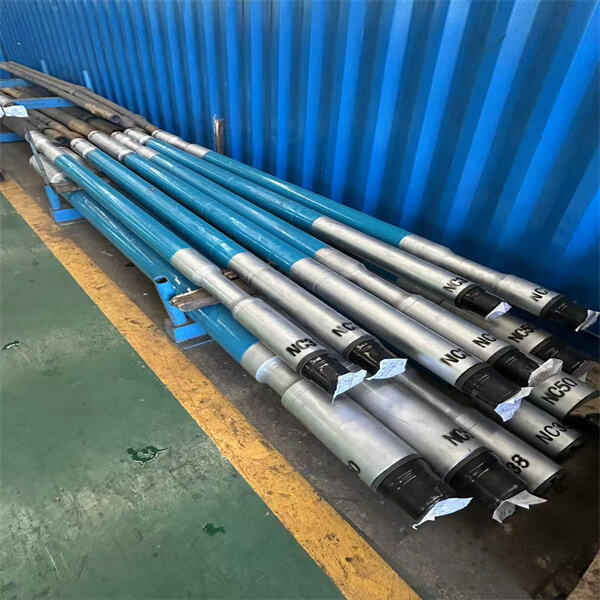

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. Deep Fast downhole tools manufacturer located Chengdu China with over 35 years of experience, was established 2008. Deep Fast offers PDC Bits various sizes and Downhole Motors various applications. They also offer full spare parts. Deep Fast utilizes a Germany modern lathe as well as Japan 5-axis NCPC to make 8000 diamond bits per year. Partner with Southwest Petroleum University for a longer-term plan, far, 50 oilfield downhole tools which includes 2 American patents, 2 Russian patents,46 Chinese patents had been gotten.

Design manufactures downhole equipment for industries oil and gas around world. DeepFast offers professional equipment teams technicians to oil and gas companies looking for high-quality, safe and reliable solutions. Quickly responsive receptive clients' questions and requests. Positive oilfield downhole tools motor (PDM) can be adapted to various Rotary Steerable Systems (RSS) or Vertical Drilling Systems (VDT). PDMs also available for Coiled Cubing as well as Short Bit to Bend PDM are also available. Provide PDC Bit, Core Bit, Bi-Center Bit, Impregnate Drill Bit, etc. Drill Bits are available in a variety size and are able to be customized to meet the requirements of our clients.

Deep Fast's Integrated Management System based on the ISO 14001 Environmental Standard ISO 45001:2018 Occupational Health and Safety Standards, and API Spec Q1 ISO 9001 (Quality). Deep fast will test all its products from raw materials through final product. The oilfield downhole tools of these tests will be provided to customers. Deep Fast process for managing for protecting our employees, our environment. Every process used to manufacture products will follow these steps.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. has the complete process and management system, from initial inquiry through to the design of product, manufacture, delivery. Deep Fast is able to provide every support to customers. Deep Fast oilfield downhole tools downhole equipment customers North America, South America and Russia. They also offer relevant services in the Middle East, Africa, UK. Japan, Southeast Asia. Additionally, Deep Fast can customize the product customers as per the various situations that arise, solve the problems the customers face. Deafest is committed to the principles of "Constancy", "Diligence", "Integrity", "Achievement" as well as the mission "Starting with the need for drilling and completing with client satisfaction".