How many dirt holes can they dig? If someone wants to dig a hole in the ground, he or she might use a shovel (a hand tool) or an enormous machine called a bulldozer. A bulldozer is making the job of moving all that dirt and rocks to build a railway bridge go more quickly. However, what if a person needs to dig extremely deep or hard rock is in the way? At this time, one special-purpose invention such as the DeepFast insert tooth cone bit is of great use.

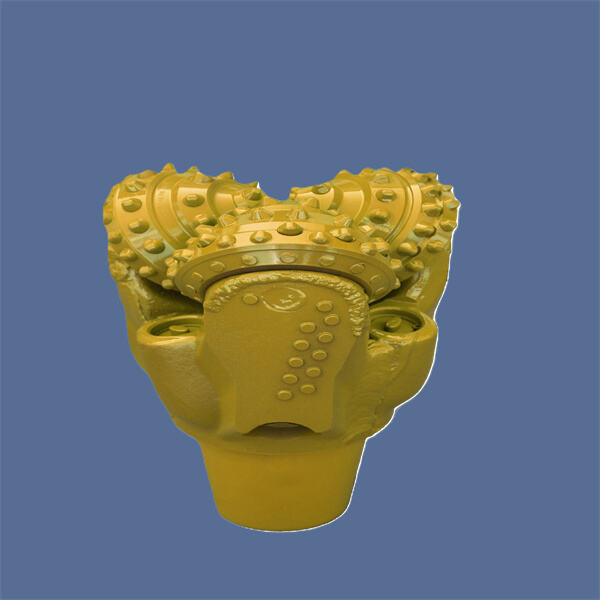

What is a steel tooth cone bit? It has a cone-shaped top of toughened steel teeth. These teeth are innocently looking but they can chew rocks or any other hard materials. These are very solid and durable, wear resistant material that can withstand a lot of pressure. This is crucial as this means workers do not have to keep replacing the tool all time.

At times, the land can be very hard when drilling go downs. Something does not have to be a stone 5 miles away with wrecking balls so large it will be difficult for you dig. However, even under such difficult conditions a steel tooth cone bit can do wonders. They can deal with challenges, and this DeepFast mill tooth tricone bit should be robust.

Cone bits are essentially the more mature version of a tricone bit and its steel teeth, as seen in above. Among these can be sandstone, a variety of rock which is often very hard and limestone another stone helped by the same description. The tapered shape of the bit also aids in directing the drilling. In that way, also the rock is easy and manageable to cut through so it becomes much easier.

It is as if attempting to take a jagged shape in paper, when snipping hard material with dull scissors. It’s really not easy, right? The identical applies for drilling in laborious rock. However, when you slice through some hardened rocks the process is a little sluggish as compared to doing it with a steel tooth cone bit.

The steel teeth fixed on the cone bit are sharp and hard. They can cut through rock faster than any other. This is one of the reasons why it makes drilling faster and easier, unlike other tools that offer only average performance. And as an added bonus, if the teeth ever get dull after a lot of use you can either sharpen them or replace it. This means that the bit can still work efficiently for a longer time, making it possible to do many more drilling projects without purchasing another tool.

The bit has a cone shape that is very helpful in guiding the drilling thus saving more of your energy during this lengthy operation. This ultimately results in higher drilling rates. Moreover, the DeepFast core drill for steel enable you to drill through anything stronger so that you are not forced into putting in too much effort. Therefore, the task will be done sooner. Getting the job done faster: many times, employees have other work to do and it is critically important in jobs where time matters.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. Deep Fast downhole tools manufacturer located Chengdu China with over 35 years of experience, was established 2008. Deep Fast offers PDC Bits various sizes and Downhole Motors various applications. They also offer full spare parts. Deep Fast utilizes a Germany modern lathe as well as Japan 5-axis NCPC to make 8000 diamond bits per year. Partner with Southwest Petroleum University for a longer-term plan, far, 50 Steel tooth cone bit which includes 2 American patents, 2 Russian patents,46 Chinese patents had been gotten.

Deep Fast Oil Drilling Tools., Ltd. can offer services its clients. From the initial enquiry, through creation of product to manufacturing process, until the delivery of the product, Deep Fast has a complete management system. Deep Fast offers downhole tools customers in North America, South America and Russia. They also offer pertinent services to the Middle East, Africa, UK. Japan, Southeast Asia. Deep Fast also customizes product meet Steel tooth cone bit needs of the client, in accordance with the particular situations that they are facing. Deafest sticks to the values of "Constancy", "Diligence", "Integrity", "Achievement" as well as the mission "Starting with the drilling requirements and ending with satisfaction of the client".

Deep Fast's Integrated Management System is based ISO 14001:2015's Environmental Standard, ISO 45001:2018 Occupational Health Safety Standards, as well as API Spec Q1 ISO 9001 (Quality). From raw materials products, deep fast will take strictly test measures ensure the quality their products, results tests will be provided to customers. Then, about the HSE, Deep Fast have Steel tooth cone bit system to protect employees and ensure protection of our environment, each manufacturing procedure be governed by these rules, every month hold the safety meetings and internal training, while some important employees will be involved in professional training outside.

Design manufacture downhole tools for the companies the oil and gas industry across globe. Deep Fast deploys professional equipment and technical teams to service the oil and gas industry seeking safe, efficient and secure solutions. Rapid response quick responses to the client's needs concerns. Positive Displacement Motor (PDM) is able to adapt to various Rotary Steerable System (RSS) as well as Vertical Drilling System (VDT). Steel tooth cone bit, they manufacture Short Bit to Bent PDM In addition, PDM for Coiled Cubing is available. PDC Bits Core Bits and Bi-Center Bits, Impregnated Drill Bits, and more. are available. Drill Bits are offered in various sizes and are able to be customized to meet the requirements of our clients.