هناك اختراع رائع في عالم الحفر يُسمى DeepFast آلة حفر نووي قطر 152 مم التي أثرت تأثيرًا هائلًا إيجابيًا على مدى نجاح واستمرارية عمليات الحفر لدينا. تتميز هذه القطع الصغيرة بقدرات عالية مقارنة بحجمها، وتُستخدم في صناعات استكشاف النفط والغاز، التعدين والبناء. في هذا المنشور، سنناقش بالتفصيل الخصائص الفريدة التي تجعل من القطع ذات حجم 8 مم (PDC) الخيار الأول لتشكيلات الأرض القاسية، حيث سنتناول ميزاتها وتقنيات الأداء الاستثنائية بالإضافة إلى أمثلة عملية على الإنجازات.

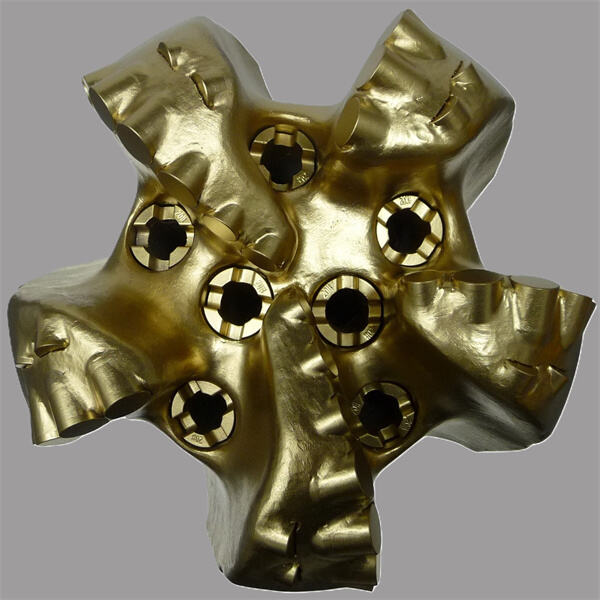

المكونات والتصميم الخاصة بـ DeepFast رأس حفر ماسي بـ4 شفرات هم المسؤولون عن قوتهم الاستثنائية. على عكس المغاليق التقليدية المصنوعة من كربيد التنجستن، يتكون مغاليق PDC من طبقة إضافية (مُحفَّزة) من الماس الصناعي المطبق على قاعدة من كربيد التنجستن مما يوفر الصلابة وحماية ضد التآكل. هذه التركيبة الخاصة تسمح لمغاليق PDC بقطر 8 ملم بتقطيع التكوينات الصخرية القاسية مثل الزبد بينما تحتفظ بحافة حادة لفترة أطول من عمر المغاليق العادية. بسبب حجمها الصغير، فإنها تتيح مستويات أكثر كثافة من المغاليق على رؤوس الحفر، مما يؤدي إلى معدلات حفر أسرع وانخفاض في العزم والجر، مما يوفر في التكاليف التشغيلية.

DeepFast حفرة نواة قطرها 160 مم التحكم في مناظر الحفر بفضل التطور المستمر في علوم المواد وعمليات التصنيع. تضمن طرق تصنيع الماس المتقدمة جودة مستمرة على مدار العملية، عند دمجها مع عمليات التصنيع الدقيقة القادرة على إنشاء ملفات حادة معقدة مخصصة لاحتياجات الحفر المختلفة. تم تصميم هذه القطّاعات لتتحمل درجات الحرارة والضغوط العالية التي تكون شائعة في الظروف الجوفية العميقة، مما سيساعد ليس فقط في زيادة عمر رأس الحفر ولكن قد يحسن كفاءة الحفر بشكل كبير. وبالتالي، أصبحت الآن المعيار الصناعي لتطبيقات الحفر عالية الأداء عالميًا.

كل محرك DeepFast محرك بقطر 73 مم تم تصميمه من عملية تصنيع تعتمد على شراكة بين صلابة الكربيد التنغستين وصلادة الماس. كل شيء يبدأ بإنشاء قطعة أولية من الماس متعدد البلورات (PCD) تحت درجات حرارة وضغوط عالية، ثم ربطها بقاعدة من الكربيد التنغستين القوي. يؤدي هذا التوليف إلى عنصر قطع أقوى وأكثر دواماً لمواجهة تحديات بيئات الحفر الصعبة. بالإضافة إلى ذلك، تم تقديم تقنيات مثل طلاء الماس المثبت حرارياً لتمديد عمر القطع من خلال توفير حماية حرارية أفضل ضد البيئات العالية الحرارة والخشنة.

شركة Sichuan Deep Fast Oil Drilling Tools Co., Ltd. Deep Fast هي شركة تصنيع أدوات الحفر تحت الأرض مقرها في تشينغدو، الصين، ولديها خبرة تمتد لـ 35 عامًا، تأسست في عام 2008. توفر Deep Fast رؤوس حفر PDC بأحجام مختلفة ومحركات حفر يمكن استخدامها في عمليات متعددة، كما تقدم قطع غيار كاملة. يتم تنفيذ العمليات باستخدام ماكينات CNC الحديثة ذات المحاور الخمس من اليابان وماكينات لحام ألمانية حديثة. كل عام، تنتج Deep Fast 10,000 قطعة من رؤوس الحفر PDC بقطر 8 مم و2000 محرك حفر تحت الأرض. جامعة البترول جنوب غرب الصين قد تعاونت معنا لعدة سنوات. حتى الآن، حصلت الشركة على 50 براءة اختراع، منها براءتان أمريكيتان وبراءتان روسيتان.

تصميم وتصنيع الأدوات تحت الأرضية لصناعات النفط والغاز في جميع أنحاء العالم. تستخدم Deep Fast معدات فنية ذات مهارات عالية بالإضافة إلى فرق تقنية لتوفير حلول آمنة وكفiciente للمصانع العاملة في صناعة النفط والغاز. يتميزون بالاستجابة السريعة والمرونة تجاه مخاوف وطلبات العملاء. قاطع الإزاحة الموجبة 8mmPDC (PDM) يمكن تكييفه مع أنظمة التوجيه الدوراني المختلفة (RSS) أو أنظمة الحفر العمودي (VDT). بالإضافة إلى ذلك، يتم تصنيع القطر القصير للبت المنحني PDM، وكذلك توفر PDM Coiled Cubing. نقدم بت PDC، وبت النواة، وبيت ثنائي المركز، وبت المغروس، وما إلى ذلك. تكون بيوت الحفر متاحة بعدة أحجام ويمكن تخصيصها لتلبية متطلبات عملائنا.

طورت Deep Fast نظام إدارة متكامل يتبع إرشادات API Spec Q ISO 9001:2015 (الجودة)، ISO 45001:2018 (الصحة والسلامة المهنية)، وISO 14001:2015 (البيئة). من المواد الخام وحتى المنتجات، ستقوم Deep Fast بإجراء اختبارات قاطع PDC 8 مم لضمان جودة المنتجات العالية. سيتم توفير نتائج الاختبارات للعملاء. كما هو الحال بالنسبة لـ HSE، لدي شركة Deep Fast نظام أمان يحمي موظفينا ويحافظ على البيئة، حيث تخضع كل عملية تصنيع للمنتجات لهذه الإرشادات. كل شهر، ستعقد الشركة اجتماع السلامة والتدريب الداخلي، وسيتم تسجيل بعض الموظفين في المناصب الحيوية في التدريب المهني الخارجي.

توفّر شركة Sichuan Deep Fast Oil Drilling Tools Co., Ltd. نظام إدارة عمليات كامل. من الاستفسار إلى تصميم المنتج، الإنتاج، التسليم، يمكن لـ Deep Fast تقديم جميع الخدمات للعملاء. تقدم Deep Fast أدوات حفر تحت الأرض والخدمات ذات الصلة للعملاء من أمريكا الشمالية، أمريكا الجنوبية، روسيا، الشرق الأوسط، أفريقيا، المملكة المتحدة، اليابان، جنوب شرق آسيا. بالإضافة إلى ذلك، يمكن لـ Deep Fast تخصيص المنتجات لعملائها بناءً على الظروف المختلفة في العمليات مثل قاطع PDC 8 ملم والتحديات التي يواجهها العملاء. لقد التزمت Deafest دائمًا بقيمة "الثبات، dicipline، النزاهة، الجدّية والإنجاز"، والرسالة "بدءًا من احتياجات الحفر الأولية وإنهاءً بالرضا عن العملاء"