تُستخدم قطع الحفر الماسية في البحث عن النفط. أصبح النفط جزءًا لا يتجزأ من حياتنا اليومية. فهو ي aliment مركباتنا، يقدم الدفء خلال الشتاء، ويضيء الظلام. العديد من الأشخاص لا يدركون تمامًا الأهمية الحقيقية للنفط في حياتنا اليومية. على سبيل المثال، لم نكن سنعرف كيف نقود إلى المدرسة أو العمل بدون النفط، ولن يتم تدفئة المنازل في الشتاء. هل تم إخبارك يومًا عن المصدر الحقيقي للنفط؟ يمكن العثور على النفط عميق تحت سطح الأرض، أميال تحت الأرض. من الصعب للغاية إخراج المادة من تحت السطح. وهذا يتطلب من العمال استخدام أدوات خاصة، واحدة من الأدوات الأساسية هي قطعة حفر ماسية تُستخدم أثناء العملية. DeepFast رأس حفر نفطي تستخدم أيضًا أدوات متخصصة مصممة لاختراق المواد الأصعب مثل الصخر والشل، حيث يوجد النفط المطلوب.

بكلمات بسيطة، يتم تثبيت قطع الماس على الطرف الصغير من كل قطعة حفر. من المعروف أن الماس هو المادة الأقسى. يمكّنهم صلابتهم من قطع الصخور المقلدة بسهولة، وأحيانًا بشكل أسرع من السكين الساخنة. الماس مثالي لاختراق الصخور الصلبة واستخراج النفط الموجود عميقاً تحت الأرض بسبب هذه الخصائص. DeepFast سعر قطعة الحفر النفطي استبدلت قطع الحفر الماسية شظايا الحفر الفولاذية قبل هذا الاكتشاف. ومع ذلك، كانت قطع الحفر الفولاذية ترتدي أو تصبح باهتة بسرعة بعد ساعات قليلة من الاستخدام، مما أبطأ بشكل كبير بناء السفن السريعة والمبنيّة بطريقة غير محكمة.

غيّرت قطع الحفر الماسية بشكل كامل صناعة حفر النفط. لقد خفضت التكلفة بشكل كبير أمام استكشاف واستخراج النفط مقارنة بأي وقت كنا نتذكره معًا. هذا المواد أكثر طولاً في الاستخدام مقارنة بالمواد الأخرى المستخدمة في الحفر وهي متينة للغاية. DeepFast الطرف الماسي لديها مستوى أعلى من المقاومة ومن الأقل احتمالاً للكسر أو التلف لأنها قادرة على تحمل درجات الحرارة والضغط العالي بشكل أفضل من أنواع أخرى من رؤوس الحفر. وهذا يؤدي إلى توفير كبير في التكاليف للشركات على الصيانة والإصلاحات، بالإضافة إلى العواقب البيئية الكبيرة الناتجة عن الحفر الواسع الذي يسبب تأثيرات سلبية على البيئة.

إحدى الأدلة الرئيسية على قوة رؤوس الحفر المصنوعة من الماس تكمن في مزاياها لاكتشاف النفط والغاز. هذا يمكّن الحفر إلى عمق أكبر في الأرض للوصول إلى احتياطيات نفط إضافية. وهذا مهم لأن هناك العديد من حقول النفط التي تقع عميقًا تحت الأرض، حيث قد لا تكون الطرق التقليدية للحفر كافية للوصول إليها بشكل صحيح. بالإضافة إلى ذلك، فإن رؤوس الحفر الماسية تصنع ثقوبًا ذات قطر صغير، مما يؤدي إلى إزالة كمية أقل من الصخور والتربة أثناء الحفر. وهذا يزيل جميع متطلبات الامتثال من عملهم، مما يؤدي إلى بيئة أكثر راحة دون التسبب بأذى. DeepFast منتجات حفر نواة الماس توليد مستويات أقل من الحرارة مقارنة بالخيارات الفولاذية. جميع هذه العوامل مهمة للغاية في تقليل فرص الحوادث والإصابات الناتجة عن ارتفاع درجة حرارة الأدوات.

القاطعات الماسية أكثر كفاءة وفعالية مقارنة بمواد الحفر الأخرى تقريبًا في كل المعايير. فهي تمتلك قوة ومتانة أكبر، مما يؤدي إلى عمر أطول دون الحاجة إلى إصلاحات. يساهم العمر الافتراضي الطويل لهذه الأدوات في تقليل الوقت المستغرق على الحفر بإزالة الحاجة لإصلاحات أو استبدال متكرر، مما يوفر وقت العمال. بالإضافة إلى ذلك، DeepFast الماس للحفر تنتج كمية أقل من نفايات القطع مقارنة بقاطعات الحفر التقليدية. حماية الكوكب والعيش بطريقة صديقة للبيئة تصبح أهمية متزايدة حيث نسعى لضمان سلامة بيئتنا للأجيال القادمة. يتم اعتبار القاطعات الماسية أكثر استدامة في عمليات حفر النفط بسبب انخفاض نسبة النفايات التي تنتجها.

شركة سيتشوان ديب فاست لأدوات حفر النفط المحدودة. شركة ديب فاست هي شركة مصنعة لأدوات الحفر تحت سطح الأرض ومقرها مدينة تشينغدو في الصين، ولها خبرة تزيد على ٣٥ عامًا، وقد أُسست في عام ٢٠٠٨. وتقدِّم شركة ديب فاست قواطع كربيد التنجستن المُدمَّج (PDC) بمقاسات مختلفة ومحركات تحت سطح الأرض لمختلف العمليات. كما توفر جميع قطع الغيار. وتستخدم شركة ديب فاست مخارط حديثة من ألمانيا وآلات تحكم رقمي متعددة المحاور من اليابان (5-محور) لإنتاج ٨٠٠٠ قاطع ماسي سنويًّا. وقد تعاونت معنا جامعة جنوب غرب البترول في مجال القواطع الماسية لحفر الآبار النفطية على مدى السنوات العديدة الماضية. وحصلت الشركة حتى الآن على ٥٠ براءة اختراع، من بينها براءتان أمريكيتان وبراءتان روسيتان.

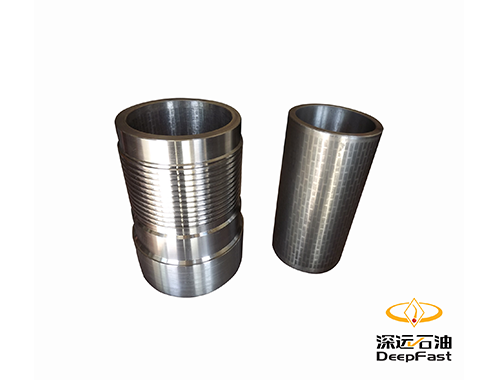

تصميم وتصنيع أدوات حفر تحت سطح الأرض للشركات العاملة في قطاع النفط والغاز على مستوى العالم. وتُوفِر شركة «ديب فاست» معدات احترافية وفرقًا فنية متخصصة لخدمة قطاع النفط والغاز، بهدف تقديم حلولٍ آمنةٍ وفعّالةٍ وموثوقة. كما تتميز الشركة باستجابتها السريعة والفعّالة لاحتياجات العملاء وشواغلهم. ويتميَّز محرك التزيح الإيجابي (PDM) بقدرته على التكيُّف مع مختلف أنظمة التوجيه الدوراني (RSS)، وكذلك مع أنظمة الحفر الرأسي (VDT). وتُصنَّع الشركة ثقوب الحفر الماسية، بالإضافة إلى إنتاج ثقوب قصيرة (Short Bit) ومحركات PDM منحنية (Bent PDM)، كما تتوفر أيضًا محركات PDM الخاصة بالحفر باستخدام أنابيب لولبية (Coiled Tubing). وتشمل المنتجات المتاحة: ثقوب الحفر ذات الأجزاء الماسية المُدمَجة (PDC Bits)، وثقوب أخذ العينات (Core Bits)، وثقوب الحفر ثنائية المركز (Bi-Center Bits)، وثقوب الحفر المُشرَّبة (Impregnated Drill Bits)، وغيرها. وتُقدَّم ثقوب الحفر بمقاسات مختلفة، ويمكن تخصيصها وفقًا لمتطلبات عملائنا.

تقدم شركة ديب فاست ل أدوات الحفر بالزيت السريع المحدودة جميع أنواع الخدمات لعملائها. فمنذ الاستفسار الأولي ومرورًا بتصميم المنتج، وتصنيعه، وانتهاءً بتوصيله، تمتلك شركة ديب فاست نظام إدارةٍ متكاملٍ. وتقدِّم ديب فاست خدمات متعلقة بالمعدات المستخدمة في أعماق الآبار لعملائها في أمريكا الشمالية وأمريكا الجنوبية وروسيا والشرق الأوسط وأفريقيا والمملكة المتحدة واليابان وجنوب شرق آسيا. كما ستقوم ديب فاست أيضًا بتعديل المنتج ليتوافق مع قطعة الحفر الماسية الخاصة بالعميل وفقًا للظروف الخاصة التي يواجهها. وقد التزمت ديب فاست دائمًا بمبدئَي «الثبات والنزاهة، والعزم والإنجاز»، وهدفها هو «البدء من احتياجات الحفر الأولية والانتهاء برضا العميل التام».

طوّرت شركة ديب فاست نظام إدارة متكامل يتبع إرشادات المواصفة القياسية API Spec Q1 وISO 9001:2015 (الجودة)، وISO 45001:2018 (الصحة والسلامة المهنية)، وISO 14001:2015 (البيئة). وستقوم شركة ديب فاست باختبار جميع المنتجات ابتداءً من المواد الخام وحتى المنتج النهائي، وسيتم إرسال تقارير هذه الاختبارات إلى العملاء. ولدى شركة ديب فاست نظام إدارة يحمي موظفينا وملحقات حفر النفط الماسية الخاصة بنا. وستلتزم كل إجراءات التصنيع بهذه المعايير.

لقد غيرت البتات الماسية بشكل كبير طريقة استخراج النفط. فهي لا تساعدنا فقط في العثور على حقول نفط جديدة لا يمكن الوصول إليها بطريقة أخرى، ولكنها تُحسّن أيضًا عملية الحفر من حيث التكلفة والكفاءة. يزداد قيمة النفط، وهو ضروري لصناعة النفط لأن العالم بأسره يعتمد عليه. مع مرور الوقت، من المتوقع أن تصبح DeepFast قطعة حفر ماسية أكثر أهمية تدريجيًا. بسبب إنتاجها العالي للطاقة وفعاليتها وإنتاج النفايات القليلة، يتم استخدامها على نطاق واسع في استكشاف النفط. بشكل عام، تثبت البتات الماسية فائدتها الكبيرة في عملية حفر النفط. فهي أكثر قوة وكفاءة بكثير من الأدوات المستخدمة سابقًا، بالإضافة إلى أنها تعيد المساءلة إلى عملية تطوير النفط من أجل البحث المسؤول عن مصادر طاقة إضافية. بدون أدوات الحفر الماسية، لا يمكن توقع مستقبل عمليات حفر النفط، وفقًا للمختصين في تقنية النفط الدولية.