Downhole drilling equipment is what enables us to extract these necessary resources such as oil and gas from deep under the surface of our planet. Our cars are able to run, and our homes can be heated with this energy source that is essential for electricity. In the world of downhole drilling equipment, we will take some closer look today to understand how it works and why is so important.

Importance of Downhole Drilling Equipment

Downhole drilling equipment is not a thing we may talk about all the time but it affects when it comes to our lives. We would have difficulty in reaching much of the personal wealth and resources we now use to power our modern lifestyle. Downhole drilling equipment has been meticulously designed to optimise efficiency and productivity, from the machinery used through to the way in which it operates.

Why Efficient Drilling Is Your Greatest Weapon

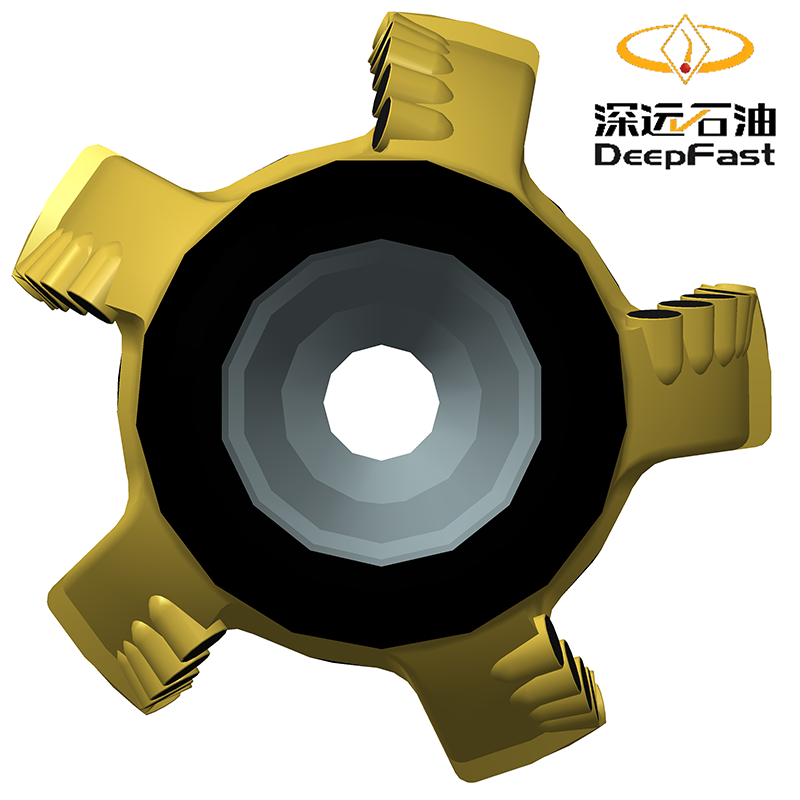

Downhole drilling equipment is made using a combination of scientific principles and engineering knowledge to attain the best possible performance. It includes several drilling by which require a optimum machine specifically for vertical & horizontal. One of the most critical parts is in this equipment are drill bits because they play a key role to dig into earth surface and access oil or gas from beneatheregenic pool under ground.

Operating and maintaining downhole drilling equipment requires great skill. The operator has to have its things dialed in, not only with the machinery and equipment but also understanding geological and environmental conditions impacting sites being drilled. This includes regular maintenance work car inspection, repairing it if needed and lubricating the same so as to increase its performance life spanurations.

Downhole drilling tools have rapidly evolved in the last few years to radically alter oil and gas sector. These improvements not only increase efficiency and reduce cost but also open the door to new sources of energy. Even today, new technology allows us to find and access more of our resources all over the world.

Downhole drilling equipment represents a backbone of the energy industry, that lets us capture and use resources we need in our current lives. From here, there are likely further innovations that will be developed as technology progresses - bringing with it a new era of oil and gas exploration. Each development brings us one step closer to a cleaner and more energy-efficient future.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. offers a complete process management system. From inquiry to design product, production, delivery, Deep Fast can provide all service to customers. Deep Fast offers downhole tools as well related services customers from North America, South America, Russia, Middle East, Africa, UK, Japan, Southeast Asia. Furthermore, Deep Fast can customize products its customers based on the different situations in operation downhole drilling equipment the challenges that customers encounter. Deafest has always adhered to the value of "Constancy Discipline, Integrity, Diligence and Achievement", the mission of "Starting at the beginning of drilling needs and finishing with satisfaction from customers".

Deep Fast's Integrated Management System is based on the ISO 14001:2015 Environmental Standard, ISO 45001:2018 Occupational Health Safety Standards, and API Spec Q1 ISO 9001 (Quality). Deepfelt will test all its products from raw materials downhole drilling equipment the final product. reports of tests will be made available customers. After that, we will inform customers about the HSE, Deep Fast have management system protects our staff, safeguard environment, every process used manufacture a product will follow these measures, every month will hold the safety meeting and training internal, some key position staff will participate training for professionals outside.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. was founded in 2008 and has over 35 years' experience downhole tools, located in Chengdu, China, Deep Fast can provide PDC Bits different dimensions, Downhole Motor used various operating conditions, complete spare downhole drilling equipment the tools. Deploy Japan 5-axis NCPC Germany Modern lathes, DeepFast manufactures annually 8000 diamond bits and 2000 downhole motor. Southwest Petroleum University has been cooperating with us several years. In the past, 50 patents have been received with 2 of them being American patents and two Russian patents.

Design manufacture downhole tools serve oil gas industries all over world. Deep Fast uses professional equipment technical teams support oil and gas companies searching for efficient, safe, efficient solutions. Rapid response responsiveness customer's requests questions. Positive displacement motor (PDM), adaptable to various Rotary Steerable Systems (RSS) or Vertical downhole drilling equipment Systems (VDT). PDMs also available Coiled Cubing Short Bit to Bend PDM are also available. PDC Bits, Core Bits, Bi-Center Bits Impregnated Drill Pieces, and more. are available. Drill Bits are available in a variety of sizes can be customized to meet the requirements of our customers.