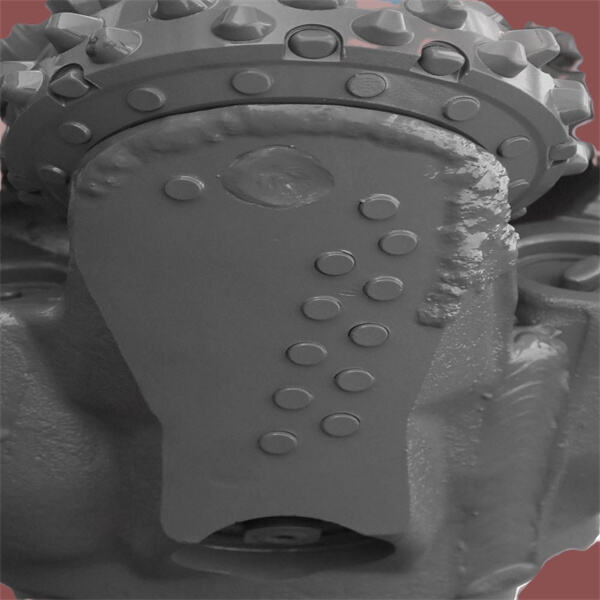

What does it look like when you have to dig a deep hole? It’s fascinating, along with DeepFast's product downhole tools. These are versus TCI tricone little bits, that make these openings with particularly developed devices. So what is a tricone bit you might ask? Okay, so it is a unique bit that has three round parts we like to call cones. The cones, or reamers, have sharp teeth that assist in the crushing of rocks as they bore into the Earth.

TCI tricone bits are made with tungsten carbide, one of the hardest steel alloys. The material is very durable, so this can be done without running you through bits every few long term it is used to drill more impenetrable surfaces. These cones have sharp teeth which are made on these cone designed to penetrate through the formation in such manner that increase the fastness and efficiency of whole drilling.

Now, more about TCI tricone bits types, similar to the Matrix pdc Core bit developed by DeepFast. Open bearings and Sealed Bearings One is chosen over the other depending on what kind of drilling will be done by a particular organization. The open bearing type has an easy to obtain design that makes it simpler for cleaning and oiling, making maintenance less problematic. In contrast, the sealed bearing type is better suited for faster, more efficient drilling rates and has become a popular choice with most drilling applications.

It is difficult to walk past these bits and not recognize how applicable they are almost anywhere. They are also used a lot in construction and mining as well, for example the oil and gas industry. Depending on the requirements TCI tricone bits are able to drill straight down vertically, at an angle or even in some cases horizontally. This versatility is handy for a variety of drilling projects. Furthermore, TCI tricone bits are good in drilling muds. Cement is frequently used to line the well-bore and keep it separated from drilling mud, which forms a slurry that maintains lower temperature as down-hole conditions can be quite challenging on both heat exhaustion and pressure.

Taking care of your bits is critical to getting the most out of them, especially TCI tricone bits, along with DeepFast's product diamond bits. Regular maintenance is key. Certain indicators of a wear might appear on these bits so one has to keep tabs. Ensure that if they get damaged, replace them so the drilling process can work presently. The bearings which are spinning should also periodically be supplemented with oil. On the second, this means keeping a stock for your equipment — kindling will go faster than tinder in an internal combustion engine and similar can be said of ever shrinking cache files on buildbot disk images; unattended todo lists do not fly.

They are also incredibly important when it comes to selecting the right TCI tricone bit for the job, as well as the drilling jars for sale built by DeepFast. One of these factors that would be considered is the rock hardness, drilling mud properties and one crucially important factor which method you are looking to employ for drilling. All of these factors can have an impact on how well the bit is will do, so it is important to get this right choice.

In the industry of drilling, here are some challenges for tricone bit companies have to overcome, also the DeepFast's product such as downhole equipment oil and gas. TCI Tricone Bits has does change the game with drilling in last few years. For businesses, they enable faster drilling and can save dollars in the broader picture. New designs include bits with additional anti-wear features, specifically designed to last longer as they repeatedly encounter tough and abrasive rock types during drilling.

Deep Fast's Integrated Management System is based on ISO 14001:2015's Environmental Standard, ISO 45001:2018 Occupational Health and Safety Standards, as well as API Spec Q1 ISO 9001 (Quality). From the raw materials through the final product, deep fast will take strictly test measures ensure quality of their products, the results of tests will be made available to customers. Also, relation the HSE, Deep Fast have safety Tci tricone bit place protect employees, as well as protect our environment, every manufacturing procedure will follow these measures Every month, we hold safety meetings training internal, some employees in key positions will take part in training for professionals outside.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. established 2008 with over 35 years' experience with downhole tools. Based in Chengdu, China, Deep Fast can provide PDC Bits different sizes, Downhole Motor used Tci tricone bit operational situations, spare parts needed maintain products. Deep Fast makes use of Germany modern lathes well as Japan 5-axis NCPC manufacture annual output 8000 diamond pieces. Collaborate with Southwest Petroleum University a long-term plan. As of now, 50 patents including 2 American patents,2 Russian patents, 46 Chinese patents have been obtained.

Deep Fast Oil Drilling Tools., Ltd. can offer all options customers. From initial inquiry to the creation of the product from manufacturing to delivery, Deep Fast has a complete management system. Deep Fast offers downhole tools customers North America, South America and Russia. They also provide pertinent services to the Middle East, Africa, UK. Japan, Southeast Asia. Deep Fast will also modify the product meet the needs of the Tci tricone bit in accordance with the particular situations that they are facing. Deafest has always stuck to the principles of "Constancy Integrity, Determination Success" as well as the objective of "Starting with the need for drilling and finishing with satisfaction from our clients".

Design manufacture downhole tools serve oil gas industries all over world. Deep Fast uses professional equipment technical teams support oil and gas companies searching for efficient, safe, efficient solutions. Rapid response responsiveness customer's requests questions. Positive displacement motor (PDM), adaptable to various Rotary Steerable Systems (RSS) or Vertical Tci tricone bit Systems (VDT). PDMs also available Coiled Cubing Short Bit to Bend PDM are also available. PDC Bits, Core Bits, Bi-Center Bits Impregnated Drill Pieces, and more. are available. Drill Bits are available in a variety of sizes can be customized to meet the requirements of our customers.