Drilling is common in sectors such as mining, construction and oil drilling. It includes creating holes in a variety of materials, such as rocks, metals and concrete with the help of specialized tools. The drill bit is one of the most essential drilling tools.

A diamond bit is a completely different type of drill that uses industrial grade diamonds. Diamond bits are used to drill into brick, granite, marble and concrete materials. They are particularly built to last a long time and does not require frequent bit replacement when drilling through robust materials.

There are things to consider when choosing a diamond bit for your drilling project so you can get the proper performance out of it. These factors include:

Material: The material that is being drilled will have a huge influence on which type of diamond bit you should use. For example, drillng through granite needs a diamond bit with high content diamonds for quick drilling.

Size of hole: The size of the hole is what will differentiate your drill bits. I can drill smaller holes using one of the standard diamond bits I have, but larger boreholes need a bigger bit.

Drilling Machine Type - Different drilling machines require corresponding types of diamond bits. Always check the diamond bit you are thinking of purchasing for use on your material against the manufacturer's specifications!

Hole depth: how deep the hole goes will also determine what type of diamond bit to use. Larger holes necessitate more advanced diamond bits with superior cooling systems to prevent overheating, and waste of the bit itself.

There are various kinds of diamond bits that come with a multitude if shapes and sizes for different purposes. There are several types of diamond bits with which most people will be familiar.

Normally use these bits for drilling of deformable formation like a softer or medium hard material, etc. in impregnated diamond while metallic matrix contains diamond particles Impregnated Industrial Diamond Bits

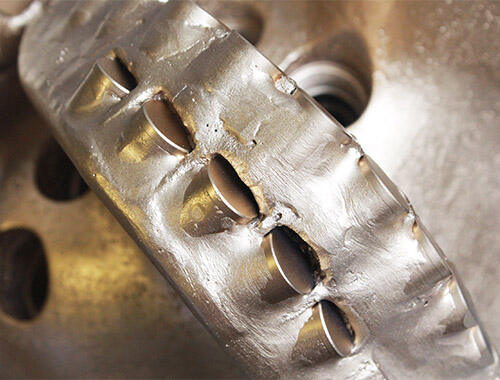

Surface set diamond bits: Diamonds are bonded onto the crown of the bit and work well when drilling soft ground such as sandstone or limestone.

PDC diamond bits: As the name implies, these incorporate polycrystalline diamond compact (PDC) cutters and are well known for their ability to effectively drill through hard materials like granite or concrete.

TSP diamond bits: Built with tungsten carbide substrate and a layer of diamond slowly attached to it, TSP diamonds allow tough materials like Limestone or Shale.

High end diamond bits have additional features that make the drilling process more efficient and effective. If you have decided to buy a diamond bit, make sure it has some of the following features -

All you need is a little amount to cover more are and the diamonds used can last about 10 times longer than lower concentrates due to better wear controlDataGridView />ChildScrollView

Sophisticated cooling: When drilling, diamond bits can heat up and to prevent damage a suitable level of cooling is needed High-quality bits include sophisticated cooling systems to reduce heat build-up and extend bit life.

Strong high-quality diamond bits are constructed with durable materials to ensure lasting performance because right drilling puts intense pressure and wear on the bit)]);

Many Uses: As diamond bits are made to drill through a wide assortment of materials they can be used in various industry.

Industrial diamonds have advanced the drilling sector across all industries, including mining, by offering faster and more productive diamond bit technology that was previously not available. We look forward to further improvements of the diamond bit technology for more enhanced drilling in future years.

Finally, as you can see that the diamond bits are important for a drilling machine and choosing from many available variants is not an easy task. Diamond bits for drilling through concrete, granite and other hard materials that will ensure quality performance in a shorter time frame. Selecting the correct diamond bit will improve drilling performance, reduce cost and maximize productivity.

Deep Fast's Integrated Management System based on ISO 14001:2015's Environmental Standard, ISO 45001:2018 Occupational Health and Safety Standards, as well as API Spec Q1 ISO 9001 (Quality). Deep fast will test all its products from materials through final products. reports of tests will be made available customers. After that, will inform customers about HSE, Deep Fast have the management system that protects the employees of our company, and protect the environment, every procedure manufacturing product diamond bit by these guidelines every month hold the safety meeting as well as training internally, some employee's key positions will take part in training professionals outside.

Create manufacture downhole tools used by oil and gas industry over globe. Deep Fast supplies professional equipment teams of technician's oil gas companies looking for safe, efficient reliable solutions. Reliable and quick respond customer questions requests. Positive Displacement Motor (PDM) is able adapt various Rotary Steerable Systems (RSS) well as Vertical Drilling System (VDT). Also manufacture Short Bit to Bent PDM diamond bit, PDM for Coiled Cubing is available. company can provide PDC Bits, Core Bits, Bi-Center Bits, Impregnate Bit, etc,. Drill Bits are available in a variety size and are able to be customized to meet the requirements our clients.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. has the complete process and management system, from initial inquiry through to the design of product, manufacture, delivery. Deep Fast is able to provide every support to customers. Deep Fast diamond bit downhole equipment customers North America, South America and Russia. They also offer relevant services in the Middle East, Africa, UK. Japan, Southeast Asia. Additionally, Deep Fast can customize the product customers as per the various situations that arise, solve the problems the customers face. Deafest is committed to the principles of "Constancy", "Diligence", "Integrity", "Achievement" as well as the mission "Starting with the need for drilling and completing with client satisfaction".

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. Deep Fast is downhole tools manufacturer located Chengdu in China with 35 years' experience, was founded in 2008. Deep Fast offers PDC Bits in various sizes and Downhole Motors that can be used various operations. also provide complete spare parts. Implement Japan 5-axis NCPC Germany Modern lathes. Each year, Deep Fast produces 10,000 diamond bit bits a 2000 downhole motor. Southwest Petroleum University has been cooperating with us for several years. As of now, 50 patents obtained which include 2 American patents two Russian patents.