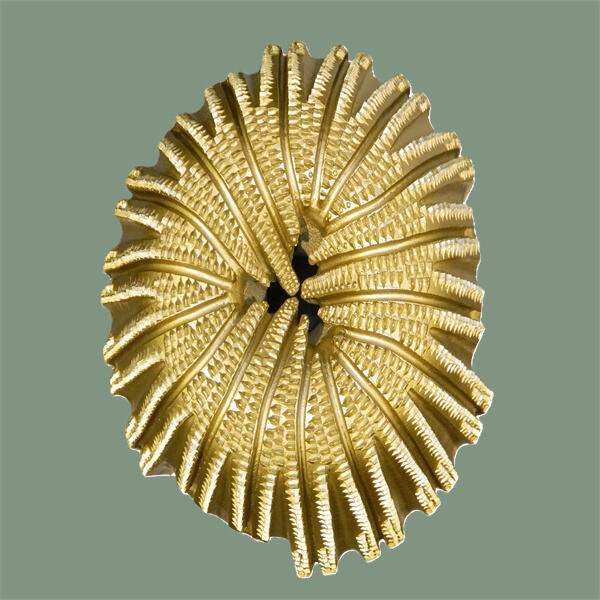

Polycrystalline diamond compact bits are tools used to bore through various materials. These bits consist of small diamonds that have been bonded and formed into a strong cutting surface. The development of polycrystalline diamond compact bits has changed the industry, making drilling quicker, simpler and more cost effective.

One of these bits upsides is its strength. The diamond crystals on the working edge are extremely hard and sharp, cutting the material much more easily than a steel blade would. This toughness gives polycrystalline diamond compact bits a faster drill rate than solid diamond drill bits, saving time and money on work.

Polycrystalline diamond compact bits have, in many respects, speeded drilling. These bits are so strong that they can often drill through hard substances such as rock and concrete. This results in a shortened time and effort for completing a drilling work. These bits are increasingly chosen today for use in mining, construction and oil and gas projects.

Polycrystalline Compact Bits Aside from being strong, Polycrystalline Diamond Compact bits are also our most robust bits. The diamond crystals can also have a much longer life than regular drill bits. This durability is very much a money saver, because you don’t need to replace them very often. It also translates into fast drilling jobs without having to change bits every so often.

Slamming down polycrystalline diamond compact bits can help drillers get better performance, more life out of the tool. Check Price On Amazon While It was not much of a problem back in the day, today everyone wants to use their bits with their impact drivers, and the irwin impact driver bits are up to the task. Their toughness and dependability allow the bits to withstand hard-use and still provide accurate hole placement.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. offers a complete process management system from inquiry design product, production, delivery. Deep Fast is able to provide every support customer. Deep Fast polycrystalline diamond compact bits downhole equipment for customers North America, South America Russia. They also provide pertinent services to the Middle East, Africa, UK. Japan, Southeast Asia. Additionally, Deep Fast can customize product for customers as per diverse situations face resolve the issues the customers confront. Deafest always adhered to core values of "Constancy and Integrity, Determination, Achievement" and the goal of "Starting with the need for drilling and finishing with satisfaction from clients".

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. Deep Fast is downhole tools manufacturer located Chengdu in China with 35 years' experience, was founded in 2008. Deep Fast offers PDC Bits in various sizes and Downhole Motors that can be used various operations. also provide complete spare parts. Implement Japan 5-axis NCPC Germany Modern lathes. Each year, Deep Fast produces 10,000 polycrystalline diamond compact bits bits a 2000 downhole motor. Southwest Petroleum University has been cooperating with us for several years. As of now, 50 patents obtained which include 2 American patents two Russian patents.

Design manufactures downhole tools used by the companies the oil and gas polycrystalline diamond compact bits across the globe. Deep Fast provides professional equipment teams of technicians to oil and gas companies seeking security, efficiency and reliability solutions. Rapid response and quick responses to customer's requests questions. Positive Displacement Motor (PDM) able adapt various Rotary Steerable System (RSS) as well as Vertical Drilling System (VDT). Also, we manufacture Short Bit to Bent PDM, in addition to, PDM for Coiled Cubing is provided. PDC Bits Core Bits and Bi-Center Bits, Impregnated Drill Bits, etc. are readily available. Drill Bits are offered in various sizes and can be customized to meet the needs of our customers.

Deep Fast developed an Integrated Management System that follows guidelines of API Spec Q1 ISO 9001:2015 (Quality), ISO 45001:2018 (Occupational Health Safety), ISO 14001:2015 (Environmental). Deep fast will test all products starting from raw materials final product. reports these tests will be sent to customers. Deep Fast has a system of management that protects our employees our polycrystalline diamond compact bits. Every procedure manufacturing product will adhere to these standards.