What is the oil rig machine or partThe drilling piece, one of them. This part goes into the ground and perforates through the rocks to take out oil or gas. But the drilling bit is a considerably more robust piece of equipment, being as it has to be strong enough survive the pressure at heat when digging deep into Earth. The machine could not fulfill the task for which it was intended — to access and drill into oil/gas deposits that lay beneath floating ice blocks translating with wave strikes up from below.

The mud pump is another critical machine working together with the drilling rig. Drilling mud is a type of liquid that machines this machine sends into the well. Drilling mud is an important component of the drilling process since it cools down for a longer period, keeps temperatures low and assists with rock removal to form pieces that come out during drilling. This mud cools the drilling bit and helps it to work properly, as well as extend its life.

For the past few years, platforms have evolved into more high-tech and sophisticated oil rig machines. Nowadays, modern oil rig machines are fortunate enough to have the help of a computer when it comes time for their task. These units have been designed to fit with sensors that help in monitoring the pressure and temperature on an ongoing basis. The data is so important, as it makes drilling operations more successful and protects the individuals involved.

This information is then processed by software that aid in ensuring efficient drilling process. Computing tasks previously done by people were becoming handled largely by computer-controlled machines. This means less scope of human error and provides you with speedy, accurate drilling automation. Companies using this technology no longer need to pay workers to operate continuously and focus on other important responsibilities, a task that drilling machinary can carry out with greater precision.

They should be checked in order to keep vulnerable devices safe. This involves performing a visual inspection, lubricating what needs to be lubed and replacing the worn out/damaged components. This makes the maintenance of these machines a lot crucial which can be done with regular oversight to avoid any breakdowns in process and also elongates their lifeline. In order for drilling to be secure and economical, good tools just have the machines.

So when an oil rig machine is up for the job, it gets to digging into the ground and hammering through rock layers some 18 feet below. A drilling bit is attached to a rotating drill pipe that grinds through the rock. Drilling mud is pumped down the drill pipe as the drilling bit digs deeper into Earth. It helps the drilling bit to be cool while it is at work and brings back loose pieces of rock so that they can examine what has been drilled into.

The deeper drilling goes, the further back from the corner that we need to move because our drill rig has to go up on top of this platform and match right at 90 feet with every length or stand of drill pipe downhole. You need to make this adjustment in order for the drilling process to continue as efficiently. The casing is then installed into the well to prevent the hole from collapsing while drilling processes are ongoing. When the casing is set and cemented in place, the drilling bit is pulled out of hole then specialized component are installed to being producing oil & gas.

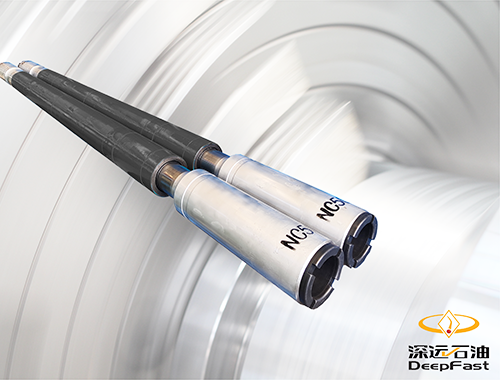

Design manufacture downhole instruments the oil and gas industry around globe. Deep Fast utilizes professional equipment technical teams service oil gas industry looking safe, efficient, reliable solutions. Quickly responsive and receptive clients' questions and demands. Positive Displacement Motor (PDM) adapts various Rotary Steerable Systems (RSS) and Vertical Drilling System (VDT). Additionally, they manufacture the Short Bit Bent PDM, additionally, PDM for Coiled Cubing offered. They offer PDC Bit, Core Bit and Impregnate Bit, etc,. with different sizes, also can customize the Drill Bits oil rig machine to the requirements of customers.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. established 2008 and has more than 35 years' experience downhole equipment, based Chengdu, China, Deep Fast can supply PDC bits various sizes, Downhole Motor used various operating conditions, and complete spare parts the oil rig machine. Deep Fast makes use Germany modern lathes as well Japan 5-axis NCPC manufacture 8000 diamond bits every year. Cooperate with Southwest Petroleum University for long term, as far,50 patents, which include 2 American patents,2 Russian patents, 46 Chinese patents have been obtained.

Deep Fast Oil Drilling Tools., Ltd. can offer all options customers. From initial inquiry to the creation of the product from manufacturing to delivery, Deep Fast has a complete management system. Deep Fast offers downhole tools customers North America, South America and Russia. They also provide pertinent services to the Middle East, Africa, UK. Japan, Southeast Asia. Deep Fast will also modify the product meet the needs of the oil rig machine in accordance with the particular situations that they are facing. Deafest has always stuck to the principles of "Constancy Integrity, Determination Success" as well as the objective of "Starting with the need for drilling and finishing with satisfaction from our clients".

Deep Fast's Integrated Management System based on ISO 14001:2015's Environmental Standard, ISO 45001:2018 Occupational Health and Safety Standards, as well as API Spec Q1 ISO 9001 (Quality). Deep fast will test all its products from materials through final products. reports of tests will be made available customers. After that, will inform customers about HSE, Deep Fast have the management system that protects the employees of our company, and protect the environment, every procedure manufacturing product oil rig machine by these guidelines every month hold the safety meeting as well as training internally, some employee's key positions will take part in training professionals outside.