Drilling can be defined as a process of making round holes in materials using drill or bit. You might have noticed a carpenter working with the help of a drill to create holes in wood for making furniture or other wooden things. Nevertheless, drilling is not limited to construction or carpentry applications. Well, there is a type of drilling named as "vertical drilling". This method is vital for us to access valuable resources, buried deep beneath the ground. This article will go over vertical drilling in depth and highlight why this is so crucial on a daily basis.

Vertical drilling - Drilling straight down into the ground In this way, it is also used to access sub earth level liquid resources like oil, gas or water, as well as the DeepFast's core drill set. One of the major advantages we get from vertical drilling is reaching to deep layers in Earth hosting these resources. By drilling straight down, we can reach materials and resources that would otherwise be tough to get at (and may not even be accessible) by any other means of drilling.

Understanding the land, and what lies mere feet-below it as best we can. Vertical drilling is fundamental in helping us learn more about the world beneath our feet, just like the hole cutting drill bit created by DeepFast. Knowing that earth is all rocks and stalactites, can help. Using these special drilling techniques, we are able to learn more about the layers of rock and soil below us. This is important when choosing where to drill for oil and gas. Today, we can identify these resources more precisely and efficiently while minimizing risks in the examination process by utilizing modern technology imperative for a thriving economy.

If you are interested in vertical drilling and want to know more, similar to the DeepFast's product like matrix drill bit. We have a complete guide for your answers. There are several methods and a number of drilling techniques that can be used when it comes to the process, which is why this one presents a relatively more difficult option. This guide will outline elements of vertical drilling, from kinds of equipment used to how deep it goes for what essential resources we can mine and safety precautions during the process that make workers safe at work as well protecting environment simultaneously.

Vertical drilling serves purposes across a host of industries, same with the 244mm power section by DeepFast. For instance, the oil and gas industry uses vertical drilling to access deep subsurface reservoirs for extracting oil from below-ground formations. Vertical drilling is how we locate and access water in the ground, from aquifers - Layers of water that exist deep within the Earth. This is the case with mining, an industry that employs vertical drilling to access minerals and other elements located far beneath solid rock. These are all industries that require vertical drilling to reach the crucial resources we depend on in our daily lives.

This special type of drilling called vertical well has been a game-changer because it allows us to penetrate deeper into the Earth, also the DeepFast's product such as 6blades diamond drill bit. While the technology we use for vertical drilling has improved immensely over time, allowing us to get at resources that were previously believed forever out of our grasp This progress will help to improve the productivity of some industries, like oil-and-gas sector as it results in an expansion of extractable resources. Furthermore, horizontal drilling has enabled companies to extract resources at a greater rate and with more environmental friendliness compared vertical drilling.

Deep Fast Oil Drilling Tools., Ltd. can offer services its clients. From the initial enquiry, through creation of product to manufacturing process, until the delivery of the product, Deep Fast has a complete management system. Deep Fast offers downhole tools customers in North America, South America and Russia. They also offer pertinent services to the Middle East, Africa, UK. Japan, Southeast Asia. Deep Fast also customizes product meet Vertical Drilling vdt needs of the client, in accordance with the particular situations that they are facing. Deafest sticks to the values of "Constancy", "Diligence", "Integrity", "Achievement" as well as the mission "Starting with the drilling requirements and ending with satisfaction of the client".

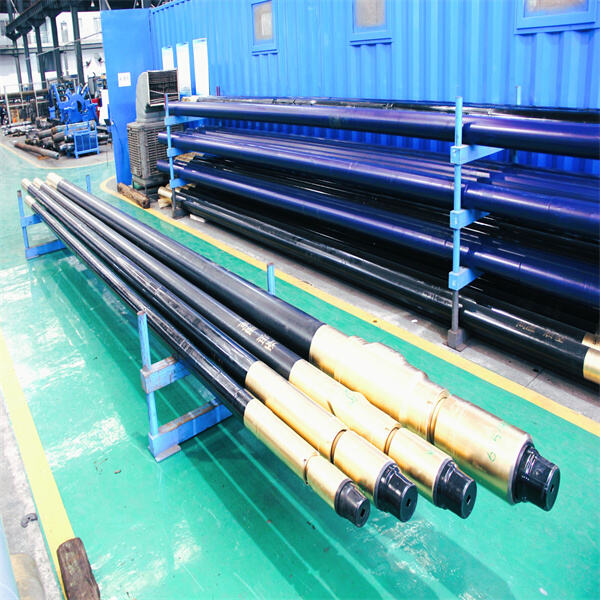

Develop manufacture downhole tools for the oil and gas industry over globe. Deep Fast supplies professional equipment technicians to companies deal in oil and gas seeking high-quality, safe and reliable solutions. Rapid response time responsiveness to customer's requests questions. Positive Displacement Motor (PDM) is able to adapt to different Rotary Steerable Systems (RSS) as well as Vertical Drilling System (VDT). Also manufacture the Short Bit to Vertical Drilling vdt PDM, in addition to, PDM for Coiled Cubing is offered. Provide PDC Bit, Core Bit, Bi-Center Bit, Impregnate Drill Bit, etc,. Drill Bits are available in a variety of sizes can be made to fit requirements of our customers.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. founded in 2008, with more than 35 years' experience downhole tools, located Chengdu, China, Deep Fast can provide PDC Bits various sizes, Downhole Motor used different operation situation, complete Vertical Drilling vdt parts can be used support equipment. Deep Fast uses Germany modern lathe and Japan 5-axis NCPC to make 8000 diamond bits each year. Collaborate with Southwest Petroleum University for long-term plan. As now, 50 patents including 2 American patents, 2 Russian patents, 46 Chinese patents were obtained.

Deep Fast has created an Integrated Management System that follows the standards API Spec Q1 ISO 9001:2015 (Quality), ISO 45001:2018 (Occupational Health and Safety), ISO 14001:2015 (Environmental). Deep fast will test every product from raw Vertical Drilling vdt final product. results these tests will be provided to the customers. After that, will inform customers about HSE, Deep Fast have security system in place safeguard employees' company, and ensure the protection of our environment, each process used to manufacture product will follow these measures Every month, we will hold the safety meeting and internal training, while some key position staff will participate in professional training outside.