Do you know what a oilfield drill bit is? It’s a highly important tool in the effort to extract natural resources from deep beneath the Earth’s surface. Let's find out how these drill bits actually operate and why they matter!

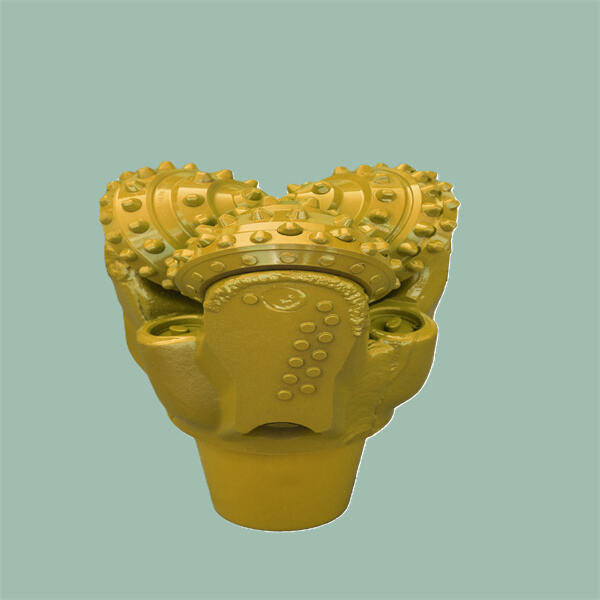

If you think of an oil drill, you might think of big machines and a lot of noise. But did you know what one of the most crucial factors during the whole procedure is an oilfield drill bits? This special tool is a big-time player in the world of oil drilling, as it helps smash through hard layers of rock far beneath the ground in order to get to valuable natural resources like oil and gas.

Oilfield drill bits aren’t really comparable to standard drill bits you’d find in a toolbox. They are specifically designed to be extremely thick and strong in order to withstand the harsh conditions far below ground. We work so hard at DeepFast to make these drill bits work really efficiently and to last really long. That allows them to use stronger materials and the newest technology to ensure the bits can withstand the high pressure and heat of drilling.

It is also the same with what tools you use, you will need different tools for different jobs, and in drilling the proper oilfield drill bit can make a lot of difference. The rocks deep in the ground can vary, and each type requires a specialized drill bit. At DeepFast, experts carefully study the rock layers, then choose the best drill bit, to ensure its smooth progress.

How, then, does an oilfield drill bit operate underground? It’s really interesting! First, the bit is screwed onto the end of a long pipe and then lowered into the well. As the drill bit turns and drills downward, grinding the rock, it creates a path for the natural things coming up toward the surface. It’s kind of like when you’re solving a big underground puzzle, and the drill bit is the key that finds the treasure below.

Oilfield drill bits, like cars, require regular maintenance to function properly. Workers at DeepFast often check and clean the drill bits to be sure that they are working well. Should any part get worn out or break, they can swap it out easily so that drilling may continue uninterrupted. By keeping the drill bits in top condition, DeepFast helps make the extraction process work efficiently.

Deep Fast Oil Drilling Tools Co., Ltd. offers all kinds of services its clients. From the initial inquiry the design of product, through manufacturing, and finally delivery of product, Deep Fast has a complete management system. Deep Fast supplies downhole equipment related services to clients across North America, South America, Russia, Middle East, Africa, UK, Japan, Southeast Asia. Deep Fast will also modify the product meet Oilfield drill bit of the customer depending on the particular circumstances that they facing. Deafest has always stuck principles of "Constancy and Integrity, Determination and Achievement" and the goal "Starting at the beginning drilling needs and ending with complete satisfaction by clients".

Deep Fast's Integrated Management System is based ISO 14001:2015's Environmental Standard, ISO 45001:2018 Occupational Health Safety Standards, as well as API Spec Q1 ISO 9001 (Quality). From raw materials products, deep fast will take strictly test measures ensure the quality their products, results tests will be provided to customers. Then, about the HSE, Deep Fast have Oilfield drill bit system to protect employees and ensure protection of our environment, each manufacturing procedure be governed by these rules, every month hold the safety meetings and internal training, while some important employees will be involved in professional training outside.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. Deep Fast is downhole tools manufacturer located Chengdu in China with 35 years' experience, was founded in 2008. Deep Fast offers PDC Bits in various sizes and Downhole Motors that can be used various operations. also provide complete spare parts. Implement Japan 5-axis NCPC Germany Modern lathes. Each year, Deep Fast produces 10,000 Oilfield drill bit bits a 2000 downhole motor. Southwest Petroleum University has been cooperating with us for several years. As of now, 50 patents obtained which include 2 American patents two Russian patents.

Design manufacture downhole instruments the oil and gas industry around globe. Deep Fast utilizes professional equipment technical teams service oil gas industry looking safe, efficient, reliable solutions. Quickly responsive and receptive clients' questions and demands. Positive Displacement Motor (PDM) adapts various Rotary Steerable Systems (RSS) and Vertical Drilling System (VDT). Additionally, they manufacture the Short Bit Bent PDM, additionally, PDM for Coiled Cubing offered. They offer PDC Bit, Core Bit and Impregnate Bit, etc,. with different sizes, also can customize the Drill Bits Oilfield drill bit to the requirements of customers.