The Rotary Steerable System (RSS) is one such important and unique tool used in drilling oil and gas. This tool improves the efficacy and efficiency of drilling. An RSS functions by steering a drill bit - the part that does all of the actual digging into heavy earth. The second system was to keep the drilling operator in perfect way. Ultimately, it is of great importance because if you goof drilling down your equipment can explode and fixing a ravaged piece of gear costs both time and money.

The use of the Rotary Steerable System (RSS) during an oil and gas drilling operation has a myriad number of benefits. The drilling performance is much better and it helps fast drill. The DeepFast steerable mud motor can control the drill bit a little better due to which it increases avoidance instead of getting through. Hence, we would consume lesser time to follow up for the mistakes that can save a lot of our energy and money.

Another big advantage that you can enjoy using the RSS decreases your risk of accidents. Because the system can direct the drill bit to exactly where it is most wanted, this sort of problem should occur a lot less frequently and make things go far more smoothly for those involved in any such processes. This in turn helps keeps drilling safe and prevents damage to the equipment involved.

A stationary BHA is typically less expensive than an RSS, which at least helps one good thing about the darn piece of antique equipment. This may seem enticing to companies looking to cut costs. On the downside, a stationary BHA is not as accurate but much better than conventional drilling. If this occurs and the drill goes beyond its intended course, you could spend a lot of time or money fixing that problem - creating more problems later on!

The less chance of accidents is the other way of work force productivity by RSS. As the DeepFast steerable downhole mud motor is able to more precisely steer a drilling bit, it could help prevent hitting unexpected stuff materials or formations that can mess up how you're trying to reach your target down hole -it makes no sense then why would use this kind of steering instead.

The Rotary Steerable System (RSS) truly revolutionized the oil and gas industry. The RSS has made drilling more cost-effective as well as an altogether higher-yielding process by granting a good deal of accuracy to the previously imprecise actions taken during oil and gas evaluation.

The RSS have also played key role in the advance safety while drilling. This DeepFast Rotary Downhole Motor allows the drill bit to be guided accurately and prevents accidents if things are unexpectedly encountered below ground. The increased safety part is import: it helps to keep the workers who do drilling alive.

Deep Fast's Integrated Management System is based on ISO 14001:2015's Environmental Standard, ISO 45001:2018 Occupational Health and Safety Standards, as well as API Spec Q1 ISO 9001 (Quality). From the raw materials through the final product, deep fast will take strictly test measures ensure quality of their products, the results of tests will be made available to customers. Also, relation the HSE, Deep Fast have safety Rotary Steerable System RSS place protect employees, as well as protect our environment, every manufacturing procedure will follow these measures Every month, we hold safety meetings training internal, some employees in key positions will take part in training for professionals outside.

Deep Fast Oil Drilling Tools., Ltd. can offer all options customers. From initial inquiry to the creation of the product from manufacturing to delivery, Deep Fast has a complete management system. Deep Fast offers downhole tools customers North America, South America and Russia. They also provide pertinent services to the Middle East, Africa, UK. Japan, Southeast Asia. Deep Fast will also modify the product meet the needs of the Rotary Steerable System RSS in accordance with the particular situations that they are facing. Deafest has always stuck to the principles of "Constancy Integrity, Determination Success" as well as the objective of "Starting with the need for drilling and finishing with satisfaction from our clients".

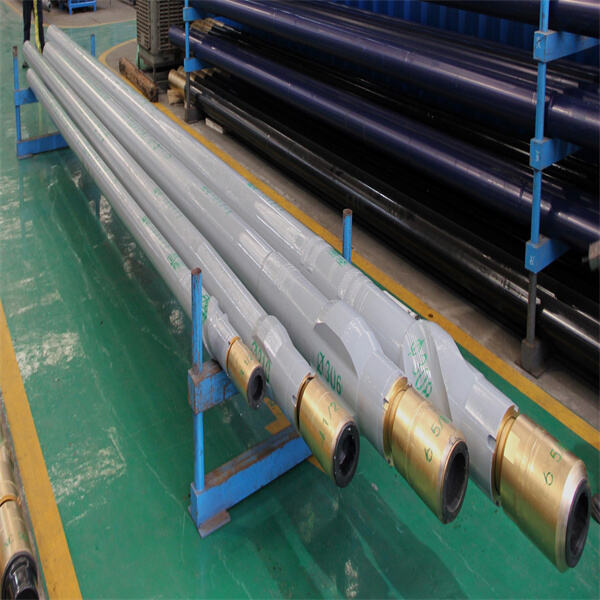

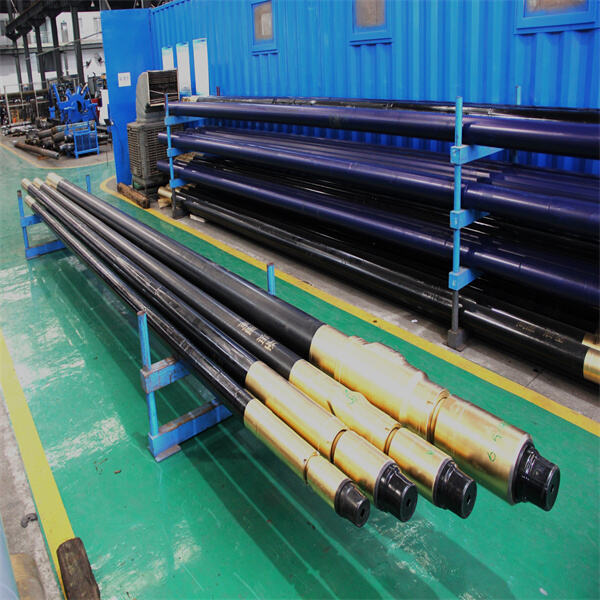

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. Deep Fast downhole tools manufacturer located Chengdu China with over 35 years of experience, was established 2008. Deep Fast offers PDC Bits various sizes and Downhole Motors various applications. They also offer full spare parts. Deep Fast utilizes a Germany modern lathe as well as Japan 5-axis NCPC to make 8000 diamond bits per year. Partner with Southwest Petroleum University for a longer-term plan, far, 50 Rotary Steerable System RSS which includes 2 American patents, 2 Russian patents,46 Chinese patents had been gotten.

Design manufacture downhole tools serve oil gas industries all over world. Deep Fast uses professional equipment technical teams support oil and gas companies searching for efficient, safe, efficient solutions. Rapid response responsiveness customer's requests questions. Positive displacement motor (PDM), adaptable to various Rotary Steerable Systems (RSS) or Vertical Rotary Steerable System RSS Systems (VDT). PDMs also available Coiled Cubing Short Bit to Bend PDM are also available. PDC Bits, Core Bits, Bi-Center Bits Impregnated Drill Pieces, and more. are available. Drill Bits are available in a variety of sizes can be customized to meet the requirements of our customers.