The TITOⓇ SS675 downhole motor(PDM) ເປັນທີ່ຮູ້ຈັກດ້ວຍຄວາມສະຖິລໃນຄວາມເວົ້າງ, ວິບວິກນ້ອຍ, ຕົວຫຼຸດຫຼາຍແລະຄວາມແຂງແຂງ, ທີ່ເປັນສະເພາະສຳລັບການເຮັດງານ core.

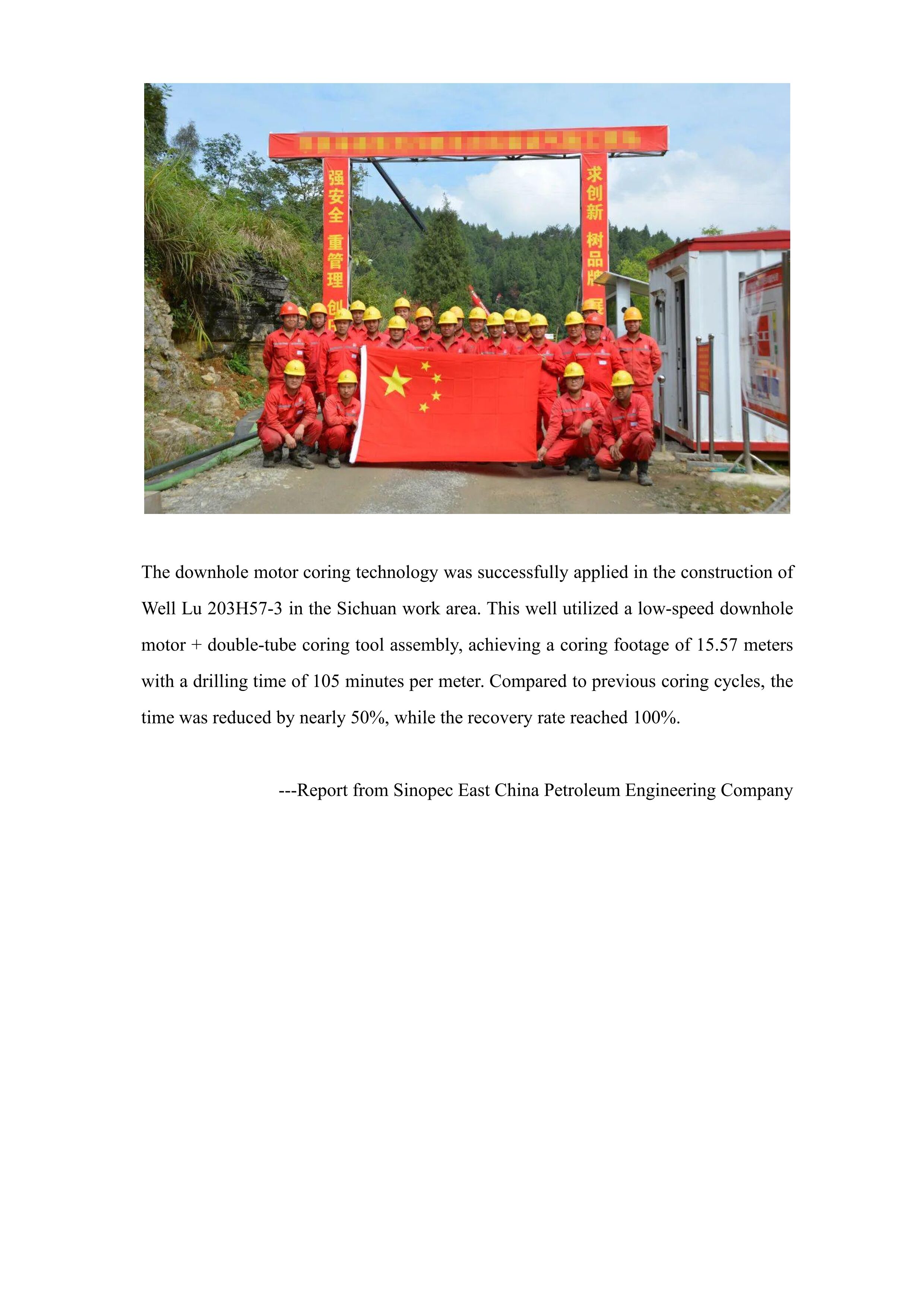

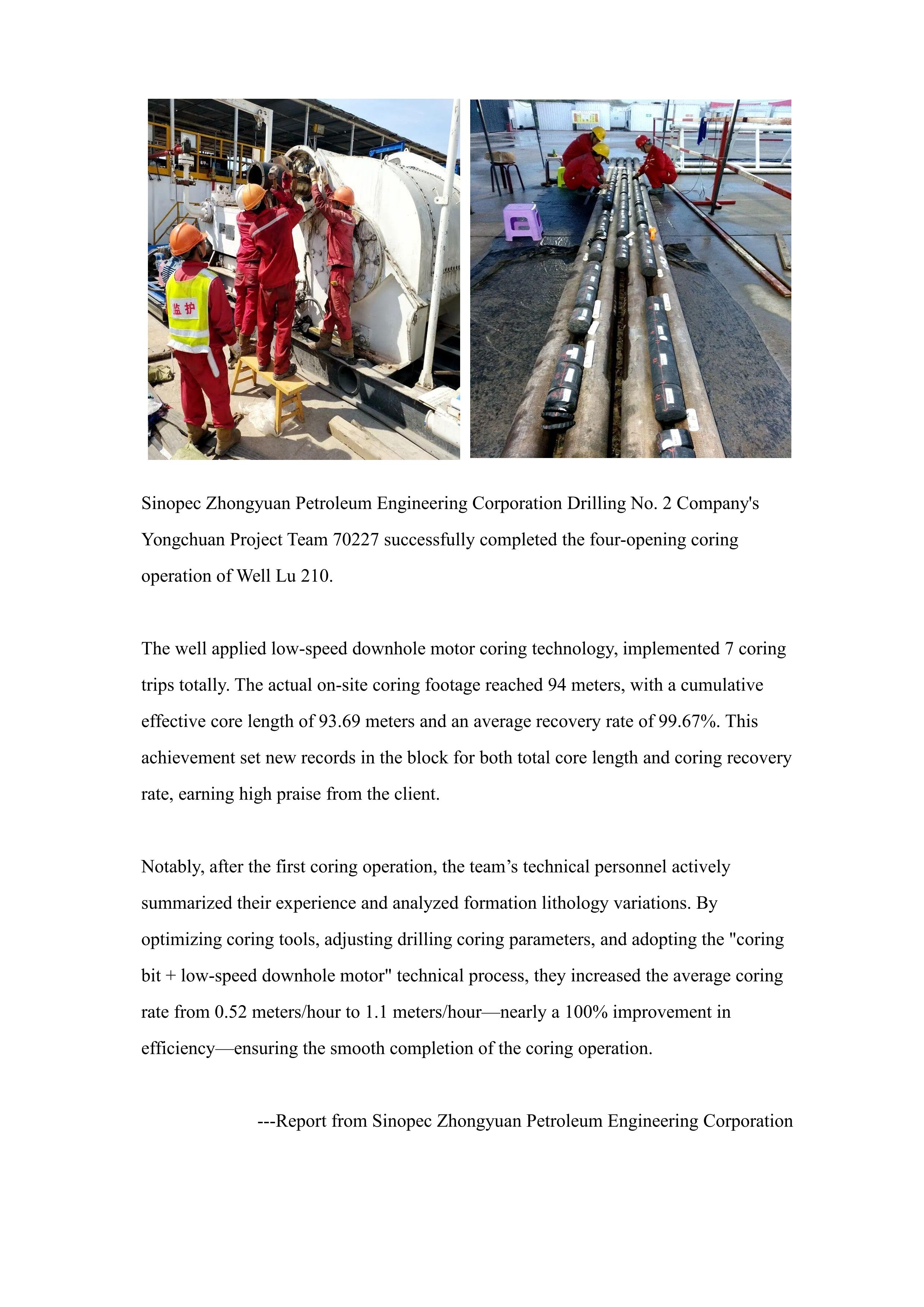

ໃນແຫວງ Lu 203H57-3 ແລະ Lu 210, ຜູ້ດູແຍງໄດ້ຕັດສິນໃຈໃຊ້ BHA ເປັນ downhole motor ຄວາມໄວຕໍ່ແລະ Coring tools. Low-speed downhole motors ໄດ້ຖືກສະໜອງໂດຍ DeepFast.