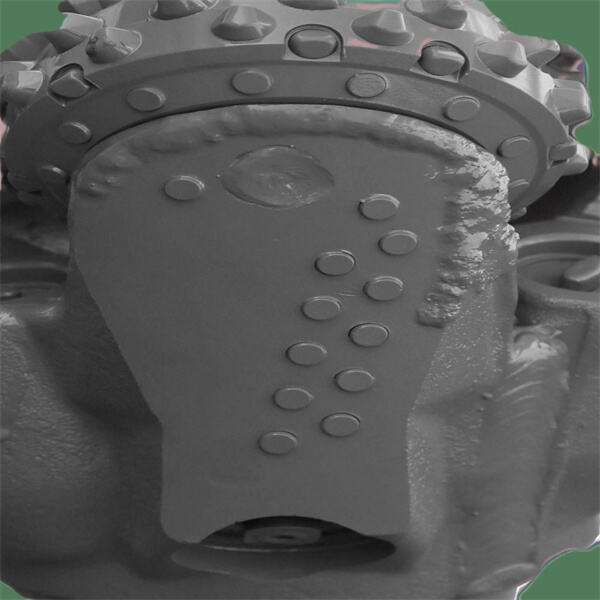

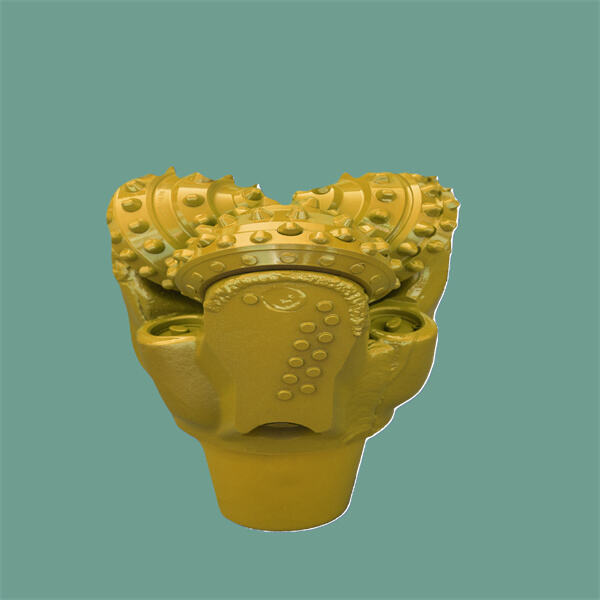

Tricone rotary drill bits are an extraordinary device used to tunnel deep inside the Earth for mining matters. This DeepFast rotary drilling rig allow them to penetrate through hard rock and earth. These have three parts made of cones which spin at a fast speed. As they rotate, they dig and crush the ground to make it more accessible for miners to get at what is underneath.

Tricone rotary drill bits have long-been a staple of all mining operations. First made in the late 1800s, so they have been around a while Over time, improvements have been made to these drill bits that make them perform better and last longer. Miners adopted these tools as their favorite because they could drill much faster than other available drilling devices back in the day. As technology evolved, so did the styles and materials used in building these awesome tools.

In order to perfect the operations of tricone rotary drill bits, manufacturers have experimented with various materials and designs. It turns out that by including hard materials, such as tungsten carbide the drill bits would be way more powerful. This DeepFast rotary drill bit are more durable and can take a beating from the hard materials they bore through. These hard metals help drill bits in doing work more effectively for the long term and also have a longer life span before replacing one. It sounds really stupid, but it saves miners time and money.

In addition to hard metals, the makers have also been experimenting with advanced materials in order for it being possible for tricone rotary bits drill successful. There are a variety of bits on the market that now have diamonds in them and this is an exciting development. Diamond impregnated bitsNo work to break very hard rocks, these diamond-impregnated will make holes. They also developed methods where powerful air or water could be fed through the borehead to aid in discharging muck from drilling operations. This will clear an area for drilling and allow the drill operate more effectively.

The tricone rotary drill bits have revolutionised the oil and gas industry. Numerous oil and gas companies have been transformed on the back of these, tools which is now a trend in finding or extracting the underground resources. This DeepFast Rotary Downhole Motor means they enable firms to drill further and faster wells than ever before, opening up new frontiers where oil and gas could be found. Intovate uses these drill bits to access reserves that were previously out of reach. This, in turn creates increased levels of production and more volumes of oil & gas drilling occurring which could lead to lower prices for consumers.

Deep Fast Oil Drilling Tools Co., Ltd. offers all kinds of services its clients. From the initial inquiry the design of product, through manufacturing, and finally delivery of product, Deep Fast has a complete management system. Deep Fast supplies downhole equipment related services to clients across North America, South America, Russia, Middle East, Africa, UK, Japan, Southeast Asia. Deep Fast will also modify the product meet Tricone rotary drill bits of the customer depending on the particular circumstances that they facing. Deafest has always stuck principles of "Constancy and Integrity, Determination and Achievement" and the goal "Starting at the beginning drilling needs and ending with complete satisfaction by clients".

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. was founded in 2008 and has over 35 years' experience downhole tools, located in Chengdu, China, Deep Fast can provide PDC Bits different dimensions, Downhole Motor used various operating conditions, complete spare Tricone rotary drill bits the tools. Deploy Japan 5-axis NCPC Germany Modern lathes, DeepFast manufactures annually 8000 diamond bits and 2000 downhole motor. Southwest Petroleum University has been cooperating with us several years. In the past, 50 patents have been received with 2 of them being American patents and two Russian patents.

Deep Fast's Integrated Management System is based ISO 14001:2015's Environmental Standard, ISO 45001:2018 Occupational Health Safety Standards, as well as API Spec Q1 ISO 9001 (Quality). From raw materials products, deep fast will take strictly test measures ensure the quality their products, results tests will be provided to customers. Then, about the HSE, Deep Fast have Tricone rotary drill bits system to protect employees and ensure protection of our environment, each manufacturing procedure be governed by these rules, every month hold the safety meetings and internal training, while some important employees will be involved in professional training outside.

Design manufactures downhole tools used by the companies the oil and gas Tricone rotary drill bits across the globe. Deep Fast provides professional equipment teams of technicians to oil and gas companies seeking security, efficiency and reliability solutions. Rapid response and quick responses to customer's requests questions. Positive Displacement Motor (PDM) able adapt various Rotary Steerable System (RSS) as well as Vertical Drilling System (VDT). Also, we manufacture Short Bit to Bent PDM, in addition to, PDM for Coiled Cubing is provided. PDC Bits Core Bits and Bi-Center Bits, Impregnated Drill Bits, etc. are readily available. Drill Bits are offered in various sizes and can be customized to meet the needs of our customers.