Let If you are one of students or another have given thought as to what lies beneath the grounds? But it is a problem that scientists and engineers are delving deep below the ground to solve. And naturally, for this exercise they use a 172mm downhole drilling motor!

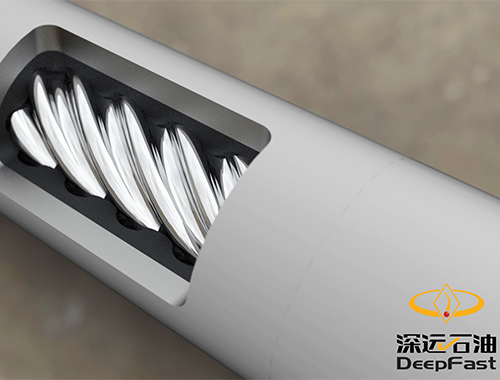

The 172mm drilling motor is far from ordinary, it's formidable and relentless in making its way through the Earth. With the ability to spin at high velocity and provide copious amounts of torque, even dense rock or clay-like grounds are no thicker than butter for this tech. This ensures fast and accurate drilling.

Importance Of 172mm Drilling Motor To Bridgehole Process This technological progression lends the capability of new drilling methods that can go deeper than before, this means mining in some remote places not attainable is more likely to happen. We can expect many new is to be found in the future, and probably a whole load of them out there yet undetectable by current methods when we have no idea what they look for or how life operates on other planets - maybe that will all change over time (some wild speculation here).

First, there are some not-so-subtle hurdles to overcome when drilling that far down: Super hot temperatures and pressure of the Earth's mantle (to put it lightly), or even just battling any other surface constantly prodding you with sneaky traps. Many of these challenges are met with the 172mm drilling motor. It is at its highest power and efficiency in the most severe operating conditions, where an increase of performance links to self-optimized drilling processes - drills are more efficient than ever even under adverse conditions.

This 172mm drilling motor is rather the key to digging secrets up and out of earth, but it doesnt work as intended or bring new insights on what lies beyond mediocrity. This amazing instrument will permit us to penetrate into our world and grow in the understanding of its mechanisms. We have this machine in our hands, and we contain infinite potentials to discover.

In essence, the 172mm Downhole drilling motor is a great revolution that has changed everything we knew about Earth exploration. Accusations of being a life line to the industry aside, this new invention is potentially capable not only be improving methods in drilling by offering more accurate and efficient results but also serve as proof that deep-drilling persists against daunting odds -to unearth whatever lurks shadowed below levels than even modern humanity though possible. Therefore, next time you are about to look down please remember: beyond this eye an unscheduled better world is upon your foot.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. is complete operation management system. From beginning with inquiry, through design of product, manufacturing, delivery, Deep Fast can provide all support to customers. Deep 172mm downhole drilling motor provides downhole equipment customers from North America, South America Russia. They also offer pertinent services the Middle East, Africa, UK. Japan, Southeast Asia. In addition, Deep Fast can customize product to meet needs customers in various situations that arise, solve the problems the customers confront. Deafest follows the principles of "Constancy", "Diligence", "Integrity", "Achievement", and the mission "Starting by addressing the needs of drilling and ending with satisfaction of the client".

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. founded in 2008, with more 35 years' experience with downhole tools, located in Chengdu, China, Deep Fast provides PDC Bits various dimensions, Downhole Motor used in different operating situations, well spare parts needed maintain the products. Deep Fast employs Germany modern lathe Japan 5-axis NCPC to make 8000 diamond bits each year. Work with 172mm downhole drilling motor Petroleum University a long-term plan. As of now, 50 patents including 2 American patents, 2 Russian patents,46 Chinese patents had been gotten.

Deep Fast's Integrated Management System is based on the ISO 14001:2015 Environmental Standard, ISO 45001:2018 Occupational Health Safety Standards, and API Spec Q1 ISO 9001 (Quality). Deepfelt will test all its products from raw materials 172mm downhole drilling motor the final product. reports of tests will be made available customers. After that, we will inform customers about the HSE, Deep Fast have management system protects our staff, safeguard environment, every process used manufacture a product will follow these measures, every month will hold the safety meeting and training internal, some key position staff will participate training for professionals outside.

Create manufacture downhole tools to serve the oil gas industries across the globe. Deep Fast provides professional equipment and technicians to companies in the oil and gas industry looking for safe, efficient and reliable solutions. Rapid response and responsiveness client's questions and requests. Positive Displacement Motor (PDM) can be adapted to various Rotary Steerable Systems (RSS) 172mm downhole drilling motor Drilling System (VDT). Also manufacture the Short Bit to Bent PDM, additionally, PDM for Coiled Cubing is provided. Provide PDC Bit, Core Bit, Bi-Center Bit, Impregnate Drill Bit, etc,. Drill Bits available in a variety of sizes and are able be designed meet the requirements of our clients.