Diamond drill bits used in the search for oil. Oil has become an integral aspect of our daily existence. It powers our vehicles, provides warmth during winter, and illuminates the darkness. Many individuals fail to grasp the true significance of oil in our everyday lives. For instance, we wouldn't know how to drive to school or work without oil, and homes in winter would be unable to be warmed. Have you ever been told the true source of oil? The oil can be found deep beneath the Earth's surface, miles underground. It is extremely difficult to remove the material from beneath the surface. This necessitates workers to utilize specific tools, with one crucial tool being a diamond drill bit utilized during the process. DeepFast oil drill bit also utilize specialized tools made to penetrate tougher substances like rock and shale, where the desired oil is located.

In simplest words, the diamond pieces are attached to the small tip of each bit. It is common knowledge that diamond is the toughest substance. Their hardness enables them to effortlessly cut through imitation rocks, at times even quicker than a heated knife. Diamonds are perfect for penetrating tough rocks to extract the oil located deep underground due to these characteristics. DeepFast oil drill bit price have replaced steel drill chips before this finding. However, steel drill bits would wear out or become blunt quickly after a few hours of use, which significantly slowed down the construction of fast and loosely built ships.

Diamond drill bits completely transformed the oil drilling industry. They have greatly reduced the cost for us to explore and extract oil compared to any time we can remember together. This material is extremely long-lasting compared to other materials used in drilling and is highly durable. DeepFast diamond bit have a higher level of resistance and are less likely to break or wear out since they are able to endure higher temperatures and pressure better than other drill bit types. This results in huge cost savings for companies on repairs and maintenance, in addition to the significant overall ecological consequences of collective extensive drilling causing negative environmental impacts.

One key proof of the strength of diamond drill bits lies in their advantages in discovering oil and gas. This enables drilling further into the ground to access additional oil reserves. This is important because there are many oil fields situated deep underground, where traditional drilling methods may not suffice to access them adequately. Additionally, diamond drill bits create holes with small diameters, resulting in the removal of minimal rock and soil when drilling. This removes all compliance inputs from their job, resulting in a more comfortable environment without causing harm. DeepFast core drill diamond products generate lower levels of heat compared to steel options. All of these factors are crucial in reducing the chances of accidents and injuries resulting from tools overheating.

Diamond drill bits are more efficient and effective than other drilling materials on nearly every measure. They possess greater strength and durability, leading to a longer lifespan without the need for repairs. The extended lifespan of the tools reduces the time spent on drilling by eliminating the need for frequent repairs or replacements, saving workers time. Moreover, DeepFast core bit diamond generate a reduced amount of cutting waste compared to traditional drill bits. Protecting the planet and living in an eco-friendly manner is becoming increasingly important as we strive to ensure the safety of our environment for future generations. Diamond drill bits are seen as more sustainable in oil drilling due to their reduced waste profile.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. Deep Fast is downhole tool manufacturer-based Chengdu in China with over 35 years' experience, was established 2008. Deep Fast offers PDC Bits various sizes and Downhole Motors different operations. They also provide all spare parts. Deep Fast uses Germany modern lathes Japan 5-axis NCPC produce 8000 diamond bits per year. Southwest Petroleum University has been Diamond oil drill bit with us over the last several years. To date 50 patents been received with 2 them being American patents as well as two Russian patents.

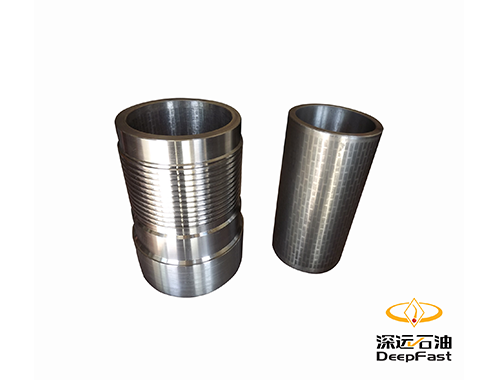

Design manufacture downhole tools for the companies the oil and gas industry across globe. Deep Fast deploys professional equipment and technical teams to service the oil and gas industry seeking safe, efficient and secure solutions. Rapid response quick responses to the client's needs concerns. Positive Displacement Motor (PDM) is able to adapt to various Rotary Steerable System (RSS) as well as Vertical Drilling System (VDT). Diamond oil drill bit, they manufacture Short Bit to Bent PDM In addition, PDM for Coiled Cubing is available. PDC Bits Core Bits and Bi-Center Bits, Impregnated Drill Bits, and more. are available. Drill Bits are offered in various sizes and are able to be customized to meet the requirements of our clients.

Deep Fast Oil Drilling Tools Co., Ltd. offers all kinds of services its clients. From the initial inquiry the design of product, through manufacturing, and finally delivery of product, Deep Fast has a complete management system. Deep Fast supplies downhole equipment related services to clients across North America, South America, Russia, Middle East, Africa, UK, Japan, Southeast Asia. Deep Fast will also modify the product meet Diamond oil drill bit of the customer depending on the particular circumstances that they facing. Deafest has always stuck principles of "Constancy and Integrity, Determination and Achievement" and the goal "Starting at the beginning drilling needs and ending with complete satisfaction by clients".

Deep Fast developed an Integrated Management System that follows guidelines of API Spec Q1 ISO 9001:2015 (Quality), ISO 45001:2018 (Occupational Health Safety), ISO 14001:2015 (Environmental). Deep fast will test all products starting from raw materials final product. reports these tests will be sent to customers. Deep Fast has a system of management that protects our employees our Diamond oil drill bit. Every procedure manufacturing product will adhere to these standards.

Diamond drill bits have significantly changed the method of oil extraction. They not only help us find new oil fields that we can't reach otherwise, but also greatly enhance the drilling process in terms of cost and efficiency. The value of oil is rising, and it is essential for the oil industry as the entire world relies on it. As time goes on, DeepFast diamond core bit are expected to become increasingly crucial. Because of its high energy output, effectiveness, and minimal waste production characteristics, it is extensively employed in oil exploration. Overall, diamond drill bits prove to be highly beneficial for the oil drilling procedure. They are significantly more powerful and effective than the tools previously used, and furthermore they reintroduce accountability to the oil development process in order to responsibly seek out more sources of energy. Without diamond drills, we cannot predict the future of oil drilling, according to experts in international petroleum technology.