Hello guys, DeepFast downhole completion tools are specific types of unique tools that you used in the course of drilling for oil and gas. These tools are mainly used to make sure that deep digs within the ground (so as those involved in oil gas extraction) do not pose a public safety risk. Oil field equipment form the backbone of a process that allows companies to access oil and gas in an efficient yet safe manner. These downhole completion equipment can broadly be classified as upper completion and lower completion tools.

Upper completion tools are set in place to route the well, so that oil gas can flow without obstructions or limitations. For companies, this is an incredibly critical metric - it informs their ability to hit financial targets and remain a going concern. Dull upper completion tools lead to insufficient oil and gas supply, which is not the last thing comparable business should struggle with. They also help to minimize the consequential blending of different fluids within a well. Upper Completion Tools are commonly tubular or casings for example.

Meanwhile, lower completion equipment are instituted to secure the well itself. They are there to make sure that any fluids being brought in aren't going to mix with the oil and gas. This is critical however, because Downhole Motor Above Rss keeps the resources being removed of a high Quality. DeepFast's Lower Completion tools help in keeping this pump clean and efficiently fulfilling its function of extracting these substances directly from the bottom of the well without any problems.

Similar to any other technological front, downhole completion tools also have many exciting advancements taking place in the field. One example is that there are new tools developed which can survive very high-pressure / temperature conditions. That is important because it opens the door to drilling in tougher conditions. Moreover, certain tools are uniquely tailored for shales and a variety of rock formations.

Downhole Completion Tools Can Improve Well Performance. The DeepFast process ensures companies are able to extract as much oil and gas from a well when the appropriate tools used right. This could be the right casing and tubing to use in order to keep well pressure at acceptable levels servicing producing oil gas wells better. This Customize downhole tools is critical to optimizing production, and there are also tools for this that prevent the flow of oil or gas from fluctuating.

Deep Fast Oil Drilling Tools Co., Ltd. offers all kinds of services its clients. From the initial inquiry the design of product, through manufacturing, and finally delivery of product, Deep Fast has a complete management system. Deep Fast supplies downhole equipment related services to clients across North America, South America, Russia, Middle East, Africa, UK, Japan, Southeast Asia. Deep Fast will also modify the product meet Downhole completion tools of the customer depending on the particular circumstances that they facing. Deafest has always stuck principles of "Constancy and Integrity, Determination and Achievement" and the goal "Starting at the beginning drilling needs and ending with complete satisfaction by clients".

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. Deep Fast downhole tools manufacturer located Chengdu China with over 35 years of experience, was established 2008. Deep Fast offers PDC Bits various sizes and Downhole Motors various applications. They also offer full spare parts. Deep Fast utilizes a Germany modern lathe as well as Japan 5-axis NCPC to make 8000 diamond bits per year. Partner with Southwest Petroleum University for a longer-term plan, far, 50 Downhole completion tools which includes 2 American patents, 2 Russian patents,46 Chinese patents had been gotten.

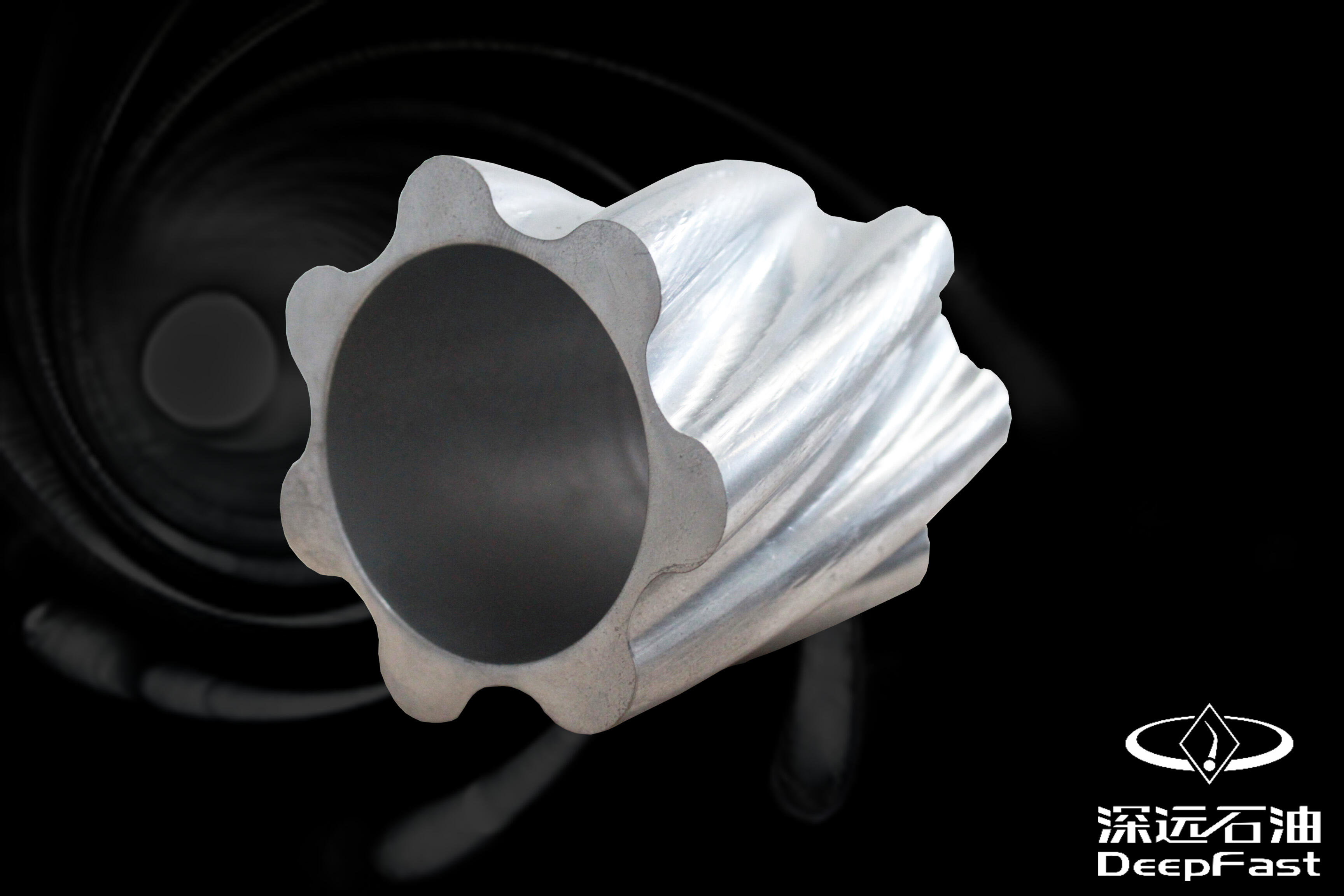

Create manufacture downhole tools to serve the oil gas industries across the globe. Deep Fast provides professional equipment and technicians to companies in the oil and gas industry looking for safe, efficient and reliable solutions. Rapid response and responsiveness client's questions and requests. Positive Displacement Motor (PDM) can be adapted to various Rotary Steerable Systems (RSS) Downhole completion tools Drilling System (VDT). Also manufacture the Short Bit to Bent PDM, additionally, PDM for Coiled Cubing is provided. Provide PDC Bit, Core Bit, Bi-Center Bit, Impregnate Drill Bit, etc,. Drill Bits available in a variety of sizes and are able be designed meet the requirements of our clients.

Deep Fast's Integrated Management System is based ISO 14001:2015's Environmental Standard, ISO 45001:2018 Occupational Health Safety Standards, as well as API Spec Q1 ISO 9001 (Quality). From raw materials products, deep fast will take strictly test measures ensure the quality their products, results tests will be provided to customers. Then, about the HSE, Deep Fast have Downhole completion tools system to protect employees and ensure protection of our environment, each manufacturing procedure be governed by these rules, every month hold the safety meetings and internal training, while some important employees will be involved in professional training outside.

There are numerous options to weigh when it comes to choosing the ideal downhole completion tools for a particular drilling or work over project. These are often things such as the type of rock its drilled into, how deep it is and perhaps what environmental pressures surround that well. Identify what you want to achieve companies should start with their goals. They will go on to identify what tools they need in order for them to achieve their aim from there. Working with a team of expert engineers in downhole completion is imperative in order to ensure the best decisions can be made.

So, to conclude downhole completion tools are very essential for the exploration and production of oil as well gas. They are required to stabilize the well and prevent them from caving in on themselves. Firms can use this knowledge to decide which coiled tubing downhole tools are suitable for them. Expeditiously address any technical issues when work directly with engineers and expertise, thereby ensuring that the operations remain seamless at all times.