Boricha amaliyoti murakkab va kamdir joyidan qiziqarli hisoblanadi. Ammo masdan foydalanish orqali uni ancha oddiy va tezroq amalga oshirishingiz mumkin. Ushbu maqola mas qanday sizning borichalariga yordam bera oladi va shu sababli avvalgi qiyinchiliklarni oldini olishni bahis qiladi.

Nechini o'zgartirganingizda, ushbu shovning uch qismi to'qilayotgan material bilan suy Ergashish. Bu suy ergashish ko'p harorat yaratadi, bu esa to'qilgich uchun yomon. Judayoni harorat to'qilgichni pozilishi va ish faoliyatining davomiyligini kamaytirishi mumkin. To'qilgich juda issiq bo'lsa, u noto'g'ri bo'lishi va kamroq efektdan foydalanishi mumkin. Maslo to'qilgichni sovuq qilish va to'qishda yuz bergan joylarni kamaytirish uchun yaxshi. Ushbu sovuq ta'siri foydali, chunki u to'qilgichlarining hayoti davomiyligini oshiradi, demak, ularni almashish kerak bo'lmaydi.

Bor yordamida maslovni etiborli ravishda ishlatiladi. Yetarlicha mas sifatiga ega emas bo'lsa — unda quruvchi barcha qatiyatlar bir-biriga yo'naltiriladi. Aksincha, ko'p masdan foydalanish toza holatni qoldirmaydi va shuni hal qilmaydi ham. Bor yordamidan keyin uni mas bilan to'la olganingizdan so'ng, bor yaxshilab o'tkazilganligiga ishonch hosil qiling. Bu bor yordamining effeksiyali va oson ishlayishi uchun kerak va borlash jarayonida issiqdan utmaydi. To'g'ri rivojlantirish muhimdir, shuning uchun siz mas miqdorini tanlashingiz drill yordamingizning ishlashida farq qilishi mumkin.

Sotuvda turli xil turdagi yaglar mavjud, lekin barcha yaglar sizning boricha qillaringiz uchun yaxshi bo'lmaydi. Agar shu haqida o'ylab korsangiz, ba'zi yaglar ular uchun maxsus ravishda ishlab chiqilmagan bo'lsa, boricha qillaringizni buzib tashlay oladi. Noto'g'ri yagni ishlatgan holda, bu qattiq yoki kamroq funktsionallikga olib kelishi mumkin. Drilling muammosi uchun to'g'ri yagni tanlash juda muhimdir. Agar siz metallga chidamayapsiz, demak, demd va poyadan foydalanadigan yaglardan foydalanishingiz kerak. Ushbu yag (va undan oxirgi) sayohat va talab qilinadigan talablarni kamaytiradi, boricha qillaringizni uzun vaqt davom etishi mumkin. Belgilarni ikki marta tekshiring, shunda siz o'z maxsus talablaringiz uchun yagni tanlaganingizdan ishonchingiz bo'ladi.

Xayr, bu sir buyuk emas, borliqlar bir qancha qimmat va asosiy vositalar tomonidan hisoblanadi, shuning uchun ularni saqlash kerak. Maslovchi qo'shsangiz, borlik tezroq xushirovga yuqolmaydi va tezda buzilmaydi. Shuning uchun maslovchini (bizning yaxshi tish yoki rustsiz bo'lish uchun kamtar odam lotyondan foydalanadi) borlik uchun muhimdir. Borlaringizni yaxshi saqlang va ular kamroq muammo bilan va uzun davom etib ishlaydi. Borlaringizni ziyoratsizlikka tekshiring va ularning yaxshi holatda saqlanishi uchun regulyar ravishda maslovchingizni qo'ying.

Siz o'z ish joyingizda o'sha va qaymoq kabi asosiy materiallardan foydalanishingiz mumkin, ammo ular faqatgina to'g'ri uslub bilan ishlatilganda uzun davom etadi. Material turini tanlash va u bilan kesishga ruhsat berilgan narsa misol sifatida, kesish uchun mas always drill bitidan eng yaxshi natijalarni olishingizga yordam beradi. Yaxshi holatda saqlangan drill bit har bir boricha amaliyotida noma'lum ta'sirlar yaratishi mumkin. Agar siz drill bitiningizning ishlashi kerak emasligini eslasangiz, unda uni tez orada remont qilishingiz kerak bo'lishi mumkin. Birinchi narsa, tozalash va yangi oil qatorini qo'yish uni mu'amalaga yetkazish uchun qulay bo'lishi mumkin. Ishlashingizni eng sodda va efektili ravishda amalga oshirish uchun uni to'g'ri ravishda saqlash kerak.

Deep Fast Oil Drilling Tools., Ltd. kompaniyasi mijozlariga xizmat ko'rsatishni taklif qiladi. Dastlabki so'rovdan boshlab, mahsulot yaratish va ishlab chiqarish jarayonigacha, shu jumladan mahsulot yetkazib berilguncha Deep Fast to'liq boshqaruv tizimiga ega. Deep Fast shimoliy Amerika, janubiy Amerika va Rossiya bo'ylab quduq osti asboblari bilan mijozlarga xizmat ko'rsatadi. Shuningdek, ular O'rta G'arb, Afrika, Britaniya, Yaponiya va Janubi-Sharqiy Osiyo mintaqalariga tegishli xizmatlar taklif qiladi. Deep Fast shuningdek, mijozlarning neftni burilish uchun g'ildiraklar (burilish qurollari) talablari va ularning duch keladigan maxsus vaziyatlarga mos ravishda mahsulotlarni moslashtirib beradi. Deep Fast "Doimiylik", "Me'yorida ishlash", "Bekorchilik", "Yutuq" qiymatlari hamda "Burilish talablari bilan boshlab, mijoz qoniqishida tugatish" missiyasiga amal qiladi.

Deep Fast integrallashgan boshqaruv tizimini, API Spec Q ISO 9001:2015 (Sifat), ISO 45001:2018 (Kasb xavfsizligi va sog'liqni himoyalash), ISO 14001:2015 (Ekologik) qo'llanmalariga muvofiq rivojlantirdi. Asosiy materiallardan mahsulotgacha, Deep Fast borliqni boring bitlari uchun sinovlar olib, yuqori sifatli mahsulotlar taminlaydi. Sinov natijalari mijozlar uchun mavjud bo'ladi. Shuningdek, HSE bilan bog'liq ishlar da, Deep Fast xodimlarimizni himoyalash va ekologik turdagi muammolardan himoya qilish maqsadida, har bir mahsulot ishlab chiqarish jarayoni bu qo'llanmalarga muvofiq bajariladi. Har oyda kompaniya xavfsizlik uchun mashq va darslar olib boradi, ulardan bir qismi esa muhim lavozimlarda ishlaydigan xodimlar tashqi professional darslarga jo'natiladi.

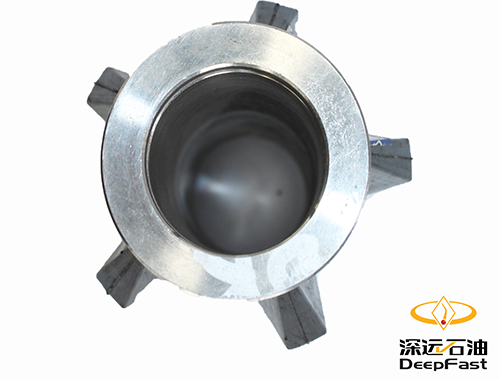

Neft va gaz sanoati uchun dunyo bo'ylab quduq ichi asboblari loyihalash va ishlab chiqarish. Deep Fast kompaniyasi neft va gaz sanoatiga xavfsiz, samarali va ishonchli yechimlar taklif qilish maqsadida professional uskunalar va texnik jamoalardan foydalanadi. Ular mijozlarning savollariga va talablariga tezda javob beradi va ularni qabul qiladi. Musbat siljish dvigateli (PDM) turli aylanuvchi boshqariladigan tizimlarga (RSS) va vertikal burilish tizimiga (VDT) mos keladi. Shuningdek, ular Qisqa burilishli PDM-ni ham ishlab chiqaradi, shuningdek, o'ralgan naylar uchun PDM-larni taklif qiladi. Ular PDC burilish uchlari, yadro burilish uchlari va impregnatlangan burilish uchlari kabi turli o'lchamlardagi burilish uchlari taklif qiladi, shuningdek, mijozlarning talablariga mos ravishda neft burilish uchlari va burilish uchlari uchun maxsus buyurtma qilish imkonini beradi.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. — 2008-yilda tashkil etilgan, quduqqa tushadigan asboblar sohasida 35 yildan ortiq tajriba mavjud. Kompaniya Xitoyning Chengdu shahrida joylashgan. Deep Fast PDC buriluvchi uchlari (turli o'lchamlarda), quduqqa tushadigan dvigatellar (buriluvchi uchlarni ishlatish uchun mo'ljallangan neftli dvigatellar), mahsulotlarni doimiy ishlashini ta'minlash uchun kerak bo'ladigan ehtiyot qismlar yetkazib beradi. Deep Fast zavodida Germaniya ishlab chiqarish usullari bilan zamonaviy tokarlik stanoklari hamda Yaponiya ishlab chiqarish usullari bilan besh o'qli NCPC (numerik boshqariladigan protsesslar) usullari qo'llaniladi; yiliga 8000 ta diamant detali ishlab chiqariladi. Kompaniya Janubiy-G'arb Neft Universiteti bilan uzun muddatli hamkorlik dasturini amalga oshiradi. Hozirgacha jami 50 ta patent (shu jumladan 2 ta AQSH patentlari, 2 ta Rossiya patentlari va 46 ta Xitoy patentlari) olingan.