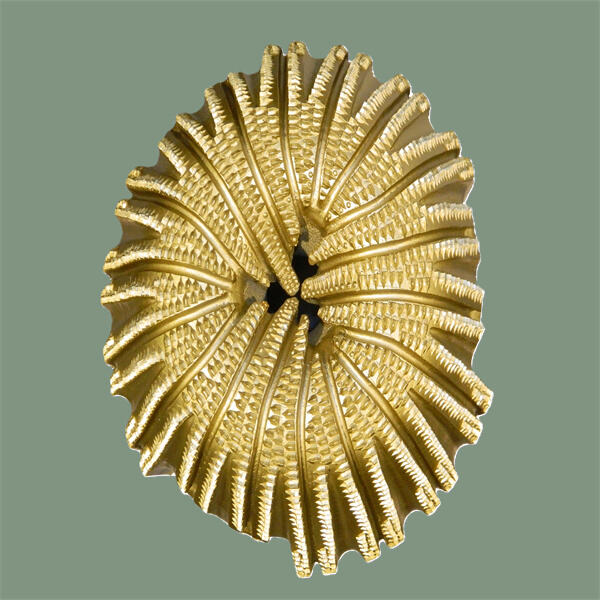

Introduction to Polycrystalline Diamond Compacts (PDCs) a polycrystalline diamond product is a super abrasive compound sintered with high hardness, excellent thermal stability and good wear resistance. Our DeepFast polycrystalline diamond compact pdc bits consists of lots and a lot of small diamond circles all put so close to each other, it's as good matching pieces of diamonds puzzle together. This material is simple in appearance, but very unique and has several neat properties. This makes it ideal for applications in mining, construction and manufacturing of things.

Polycrystalline Diamond Compact is Toughest and most Wear Resistant Bit on the Market. This means you can use it often without wear and tear with high durability. In fact it is one of the hardest substances in the world! It is capable of withstanding high heat and very low-cool temperatures without cracking or breaking. That is why it has become so famous in using tools and machinery that are required to last long with great performance.

Polycrystalline diamond compact are very good for cutting a hard material such as rock, concrete or metal. It is strong enough to cut through them, but it can only do so - with force and speed. This attribute makes machines with diamond blades such as drills and saws -with DeepFast polycrystalline diamond compact pdc bits segments- to work faster or more effectively. This is especially crucial to sectors such as mining and construction wherein fastness & correctness play an important role in carrying out the process accurately.

Polycrystalline Diamond Compact is not only super strong but it’s accurate too. Therefore, it can perform tiny and precise incisions without tearing the material. This accuracy becomes even more critical in arenas such as manufacturing and electronics where precision is everything. Products can be machined precisely with minimal waste by machines that utilize polycrystalline diamond compact (PDC) carving blade, which saves unnecessary materials and resources.

Polycrystalline diamond compact is also extremely versatile, so it can be used on many different materials and for various jobs. For example, it can even help to drill oil, mining of diamonds and cutting metal in various shapes. It is also used in some other vital aspects such as medical instruments, electronic and Aerospace engineering. This adaptability makes PDC a versatile material and enables several industries to innovate themselves by adopting it.

It has revolutionized the way in which we mine. This is shown best below with a quote from Saint Gobain. Building on success - Innovative crushed diamond and DeepFast polycrystalline diamond drill bits Impact resist S2 operates at revolutionary speed in any geological formation. Processes such as drilling for oil and mining of metals have been expedited, more secure and less complex than before. Because this change created more jobs in many popular areas and it is very good for the economy and people.

Deep Fast developed an Integrated Management System that follows guidelines of API Spec Q1 ISO 9001:2015 (Quality), ISO 45001:2018 (Occupational Health Safety), ISO 14001:2015 (Environmental). Deep fast will test all products starting from raw materials final product. reports these tests will be sent to customers. Deep Fast has a system of management that protects our employees our Polycrystalline diamond compact. Every procedure manufacturing product will adhere to these standards.

Create manufacture downhole tools used by oil and gas industry over globe. Deep Fast supplies professional equipment teams of technician's oil gas companies looking for safe, efficient reliable solutions. Reliable and quick respond customer questions requests. Positive Displacement Motor (PDM) is able adapt various Rotary Steerable Systems (RSS) well as Vertical Drilling System (VDT). Also manufacture Short Bit to Bent PDM Polycrystalline diamond compact, PDM for Coiled Cubing is available. company can provide PDC Bits, Core Bits, Bi-Center Bits, Impregnate Bit, etc,. Drill Bits are available in a variety size and are able to be customized to meet the requirements our clients.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. founded in 2008, with more 35 years' experience with downhole tools, located in Chengdu, China, Deep Fast provides PDC Bits various dimensions, Downhole Motor used in different operating situations, well spare parts needed maintain the products. Deep Fast employs Germany modern lathe Japan 5-axis NCPC to make 8000 diamond bits each year. Work with Polycrystalline diamond compact Petroleum University a long-term plan. As of now, 50 patents including 2 American patents, 2 Russian patents,46 Chinese patents had been gotten.

Deep Fast Oil Drilling Tools Co., Ltd. offers all kinds of services its clients. From the initial inquiry the design of product, through manufacturing, and finally delivery of product, Deep Fast has a complete management system. Deep Fast supplies downhole equipment related services to clients across North America, South America, Russia, Middle East, Africa, UK, Japan, Southeast Asia. Deep Fast will also modify the product meet Polycrystalline diamond compact of the customer depending on the particular circumstances that they facing. Deafest has always stuck principles of "Constancy and Integrity, Determination and Achievement" and the goal "Starting at the beginning drilling needs and ending with complete satisfaction by clients".