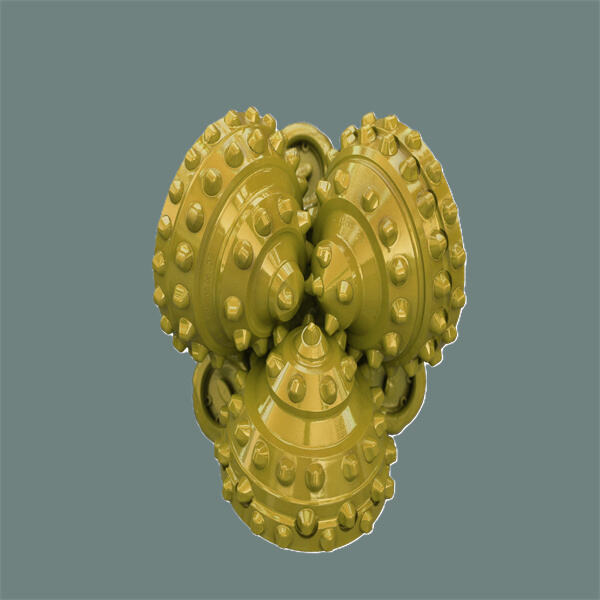

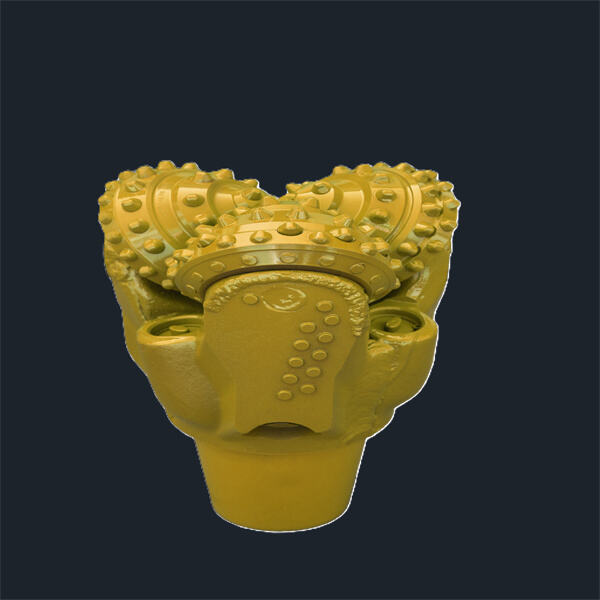

Hello, young explorers! Today, we are going to feel unique instrument which is a mill tooth tricone bit. Have you ever thought about how we drill deep down into the earth to find things like oil, natural gas, or water? These cool tools allow us to drill deep into the Earth and extract resources we need.

A steel tooth tricone bit used for drilling. One of the big benefits of a mill tooth tricone is that it’s very strong. These DeepFast bits are tough and durable, drilling with ease even in challenging conditions while attributing to a long bit life, so it’s a great option for drilling projects.

Using Your mill tooth tricone bit Properly In order for you to get the most use out of your mill tooth tricone bit, you need to use it properly. Be sure pick the correct size and design for the material you are drilling. This may help you drill more efficiently.

The tricone bit also has the bearing system. This system also assists the bit in spinning freely as you drill. Clever, based in Toronto, recommends that you look for bits with heavy bearings, to ensure that they last.

Caring for your DeepFast mill tooth tricone bit is critical. Cleaning the bit well after use will remove any built-up dirt or debris that could have an impact on how the bit performs. Inspect the tricone bit regularly for wear or damage and correct any issues as soon as possible.

Also be sure to store your DeepFast mill tooth tricone bits appropriately when you are not actively using it. Store it in a dry place to prevent rust. Give your tci tricone bit proper maintenance, and youre more likely to extend its life and get the most out of it when youre drilling.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. is complete operation management system. From beginning with inquiry, through design of product, manufacturing, delivery, Deep Fast can provide all support to customers. Deep Mill tooth tricone bit provides downhole equipment customers from North America, South America Russia. They also offer pertinent services the Middle East, Africa, UK. Japan, Southeast Asia. In addition, Deep Fast can customize product to meet needs customers in various situations that arise, solve the problems the customers confront. Deafest follows the principles of "Constancy", "Diligence", "Integrity", "Achievement", and the mission "Starting by addressing the needs of drilling and ending with satisfaction of the client".

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. Deep Fast is downhole tool manufacturer-based Chengdu in China with over 35 years' experience, was established 2008. Deep Fast offers PDC Bits various sizes and Downhole Motors different operations. They also provide all spare parts. Deep Fast uses Germany modern lathes Japan 5-axis NCPC produce 8000 diamond bits per year. Southwest Petroleum University has been Mill tooth tricone bit with us over the last several years. To date 50 patents been received with 2 them being American patents as well as two Russian patents.

Deep Fast's Integrated Management System is based ISO 14001:2015's Environmental Standard, ISO 45001:2018 Occupational Health Safety Standards, as well as API Spec Q1 ISO 9001 (Quality). From raw materials products, deep fast will take strictly test measures ensure the quality their products, results tests will be provided to customers. Then, about the HSE, Deep Fast have Mill tooth tricone bit system to protect employees and ensure protection of our environment, each manufacturing procedure be governed by these rules, every month hold the safety meetings and internal training, while some important employees will be involved in professional training outside.

Design manufacture downhole tools serve oil gas industries all over world. Deep Fast uses professional equipment technical teams support oil and gas companies searching for efficient, safe, efficient solutions. Rapid response responsiveness customer's requests questions. Positive displacement motor (PDM), adaptable to various Rotary Steerable Systems (RSS) or Vertical Mill tooth tricone bit Systems (VDT). PDMs also available Coiled Cubing Short Bit to Bend PDM are also available. PDC Bits, Core Bits, Bi-Center Bits Impregnated Drill Pieces, and more. are available. Drill Bits are available in a variety of sizes can be customized to meet the requirements of our customers.