A rotary rock bit is a specific type of tool which mainly used for the drilling holes on rocks. They are very useful and they help humans to extract minerals like gold, coal iron copper. These minerals are used in a disaggregation of industries around the conspirator and found some items on our routine we use everyday. Like gold is used in jewelry, coal for energy, iron also been frequently needed to make all buildings and copper for electrical wiring. For something as basic to our society and infrastructure, a right DeepFast rock drill bit can be the difference between progress or colossal delays. Rock drill bits are available in many different types and the top hammer tri cone rock bit contracts outfits will be able to choose which type of one is appropriate for you depending on what kind of ground that they need drilling into, as well as how big a hole it needs. Just like the different tools for various tasks you must choose an appropriate bit for each situation.

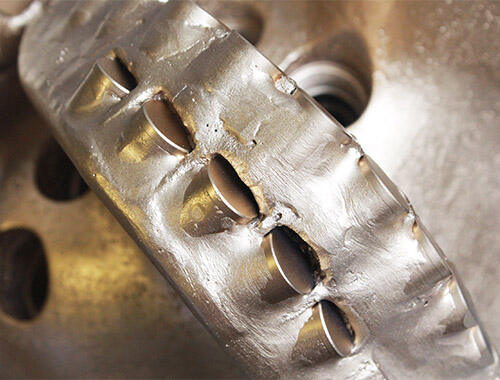

A single tool or ensemble of tools form the DeepFast rock drill bit. The human part of the drill bit is called a bit body. It is the part of your drill that makes contact with their rock and drills. Bits are most often made from very hard materials like tungsten carbide (WC) or diamond. These materials are robust enough to excavate even hard rock. The face design is related to the bit body. The body shapes of the bit work better on different rock types. For example, a spade or pyramid bit will work wonders while drilling through some difficult rocks such as granite. In contrast, a flat or chisel-shaped bit is better suited for softer rocks such as limestone. The size of hole you want to drill with rock roller drill bit in rock is also affected by the length of the bit body too.

The answer to why be so many types of rock drill bits is a simple one, and that is because there are different needs! Only some of the bits would be made for drilling straight down into the ground, and others are specifically designed to drill sideways. This matters because different types of construction projects may need to be drilled in a various direction. Some rock drill bits, for example are designed to tear into the ground at a pace that is truly quite breathtaking and others make their way through more slowly. The slower DeepFast bits are also excellent for repeatability, necessary when the hole has to be a certain fixed size and shape. A few of the bits are dead on, making holes that fit snugly while others may be looser fits. These different types of bit styles serve a useful purpose by giving the worker options for selecting the right tool that they need for their particular job.

Rock drill bits are expensive tools, so it is proper that one should take care of this kind of tool. This will make them last longer and work better ( if you take care of it properly). The best way to do this is by running the bit body cool while you are using it. If the bit gets too hot, it can damage. A high pressure hose is frequently used to spray water (or for that matter, air) on the bit to cool it down. The profile is tool cooling, ensuring that the tricone rock bit does not overheat. Also take good care of the drill rig that holds the bit. Monitoring and servicing the drill rig is a must as wear on the drilling point due to well kep conditions will help your bit perform better.

There exist various rock drill bits and each is crafted for an intended purpose. The bits produced for drilling with quality and design, pressures accurate holes in the right size of sizes. The latter are designed to get in and out as fast as can be under the circumstances, Also, some drill bits are only compatible with certain stones while others are versatile and can cut most rocks. However, some bits are made for specialized drilling rigs and others can be used on a broad swath of rig designs.

To quickly summarize - rock drill bits are simply tools for boring holes into rocks. They are invaluable in the mine for important mineral ore, and to build roads (Authoritative) railway. To our workmen, these rock drill bits are last-longing upon them rudimentary as long they know the real facts about types of bit and the scope of each meaning that if well taken care for any one type with outlast to serve you better. This knowledge is essential to tackling a project and knowing when tricone rock roller bits will go well.

Develop manufacture downhole tools for the oil and gas industry over globe. Deep Fast supplies professional equipment technicians to companies deal in oil and gas seeking high-quality, safe and reliable solutions. Rapid response time responsiveness to customer's requests questions. Positive Displacement Motor (PDM) is able to adapt to different Rotary Steerable Systems (RSS) as well as Vertical Drilling System (VDT). Also manufacture the Short Bit to Rock drill bit PDM, in addition to, PDM for Coiled Cubing is offered. Provide PDC Bit, Core Bit, Bi-Center Bit, Impregnate Drill Bit, etc,. Drill Bits are available in a variety of sizes can be made to fit requirements of our customers.

Deep Fast Oil Drilling Tools., Ltd. can offer services its clients. From the initial enquiry, through creation of product to manufacturing process, until the delivery of the product, Deep Fast has a complete management system. Deep Fast offers downhole tools customers in North America, South America and Russia. They also offer pertinent services to the Middle East, Africa, UK. Japan, Southeast Asia. Deep Fast also customizes product meet Rock drill bit needs of the client, in accordance with the particular situations that they are facing. Deafest sticks to the values of "Constancy", "Diligence", "Integrity", "Achievement" as well as the mission "Starting with the drilling requirements and ending with satisfaction of the client".

Deep Fast's Integrated Management System based on ISO 14001 Environmental Standard, ISO 45001:2018 Occupational Health Safety Standards, as well as API Spec Q1 ISO 9001 (Quality). From raw materials up products, Rock drill bit fast will take strictly test measures ensure the high-quality products. reports of tests will be available to the customers. Then, about the HSE, Deep Fast have management system protect employees, as well as protect the environment, every manufacturing procedure follows these standards every month we hold the safety meeting and training internal, some personnel in the key positions will be enrolled in professional training outside.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. founded in 2008, with more 35 years' experience with downhole tools, located in Chengdu, China, Deep Fast provides PDC Bits various dimensions, Downhole Motor used in different operating situations, well spare parts needed maintain the products. Deep Fast employs Germany modern lathe Japan 5-axis NCPC to make 8000 diamond bits each year. Work with Rock drill bit Petroleum University a long-term plan. As of now, 50 patents including 2 American patents, 2 Russian patents,46 Chinese patents had been gotten.