Ever thought about how holes are drilled deep in the surface of the Earth? Extracting oil and gas is difficult work that needs cutting-edge technology, precision machinery. One of the essential part in a drilling rig is subject to downhole motor, it drives drill bit and helps with rock/soil deformation into digged hole.

But in recent years, engineers and scientists have been chipping away at the downhole motor problem one new development at a time. Perhaps the most interesting innovations are in areas that were once considered to be relatively stable, such as bearing downhole motor design (with bearings which significantly reduce friction and wear on moving parts of motors). In this review, we will reveal how downhole motors with bearing are transforming the oil and gas industry saving drilling projects all over the world.

Drilling efficiency is something that companies are continuously trying to improve upon in an effort to lower costs and increase production. One of the ways to achieve this goal is through using hi-tech bearing downhole motors. Because the bearing motor reduces friction and wear on parts of the moving, it does not heat up as much when compared to other motors.

This improved efficiency allows for faster drilling and this makes overall productivity more efficient, it increases the precision of the drill holes that you make and also reduces maintenance costs. And remember how difficult it would be to get such drilling result without the assistance of bearing downhole motor!

With the global energy requirements growing, oil and gas companies are going to deeper & more complicated wells for source of future new energies. This effort requires advanced drilling technology able to sustain deep-drilling operations in extreme environments.

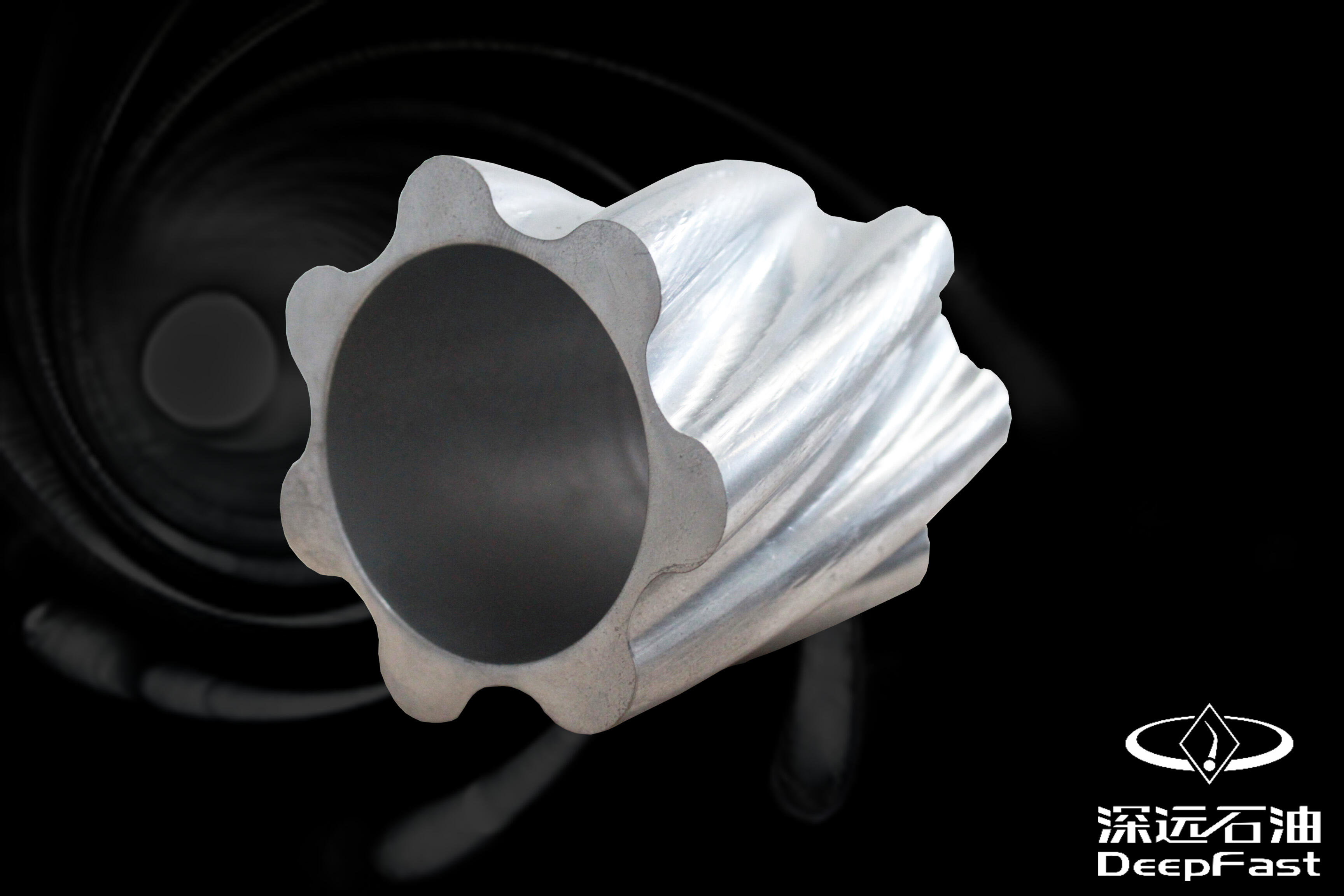

Downholeing motors bearing are especially designed for operating at high temperatures and pressure while useful unlocking the deeper reservoir. The heavy-duty design of the bearing motor is able to survive harsh drilling conditions in which uninterrupted shocks and vibrations are often caused, allowing drill rigs capable of reaching greater depths than ever before and providing access to previously unreachable oil and gas reserves.

There is an obvious benefit of a bearing within the downhole motor, but that advantage doubles as improved control and power during drilling operations. The special bearings used in the motors reduce friction and thus provide a uniform flow drilling fluid to drill bits, which increases accuracy in the system and stability.

Create manufacture downhole tools used by the companies the oil and gas industry across world. Deep Fast employs highly skilled equipment and technical teams service the oil gas industries looking for safe, efficient, secure solutions. Fastly responsive to customers' concerns as well as requests. Positive Displacement Motor (PDM) is able to adapt to different Rotary Steerable System (RSS) Vertical Drilling System (VDT). PDMs are also available for Coiled Cubing as well as Short Bit to Bend PDM are also available. PDC Bits, Core Bits, Bi-Center Bits Bearing downhole motor Drill bits, more. readily available. Drill Bits are available in a variety of sizes and can be designed to meet the requirements of our clients.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. has the complete process and management system, from initial inquiry through to the design of product, manufacture, delivery. Deep Fast is able to provide every support to customers. Deep Fast Bearing downhole motor downhole equipment customers North America, South America and Russia. They also offer relevant services in the Middle East, Africa, UK. Japan, Southeast Asia. Additionally, Deep Fast can customize the product customers as per the various situations that arise, solve the problems the customers face. Deafest is committed to the principles of "Constancy", "Diligence", "Integrity", "Achievement" as well as the mission "Starting with the need for drilling and completing with client satisfaction".

Deep Fast's Integrated Management System based on ISO 14001:2015's Environmental Standard, ISO 45001:2018 Occupational Health and Safety Standards, as well as API Spec Q1 ISO 9001 (Quality). Deep fast will test all its products from materials through final products. reports of tests will be made available customers. After that, will inform customers about HSE, Deep Fast have the management system that protects the employees of our company, and protect the environment, every procedure manufacturing product Bearing downhole motor by these guidelines every month hold the safety meeting as well as training internally, some employee's key positions will take part in training professionals outside.

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. Deep Fast is downhole tools manufacturer located Chengdu in China with 35 years' experience, was founded in 2008. Deep Fast offers PDC Bits in various sizes and Downhole Motors that can be used various operations. also provide complete spare parts. Implement Japan 5-axis NCPC Germany Modern lathes. Each year, Deep Fast produces 10,000 Bearing downhole motor bits a 2000 downhole motor. Southwest Petroleum University has been cooperating with us for several years. As of now, 50 patents obtained which include 2 American patents two Russian patents.