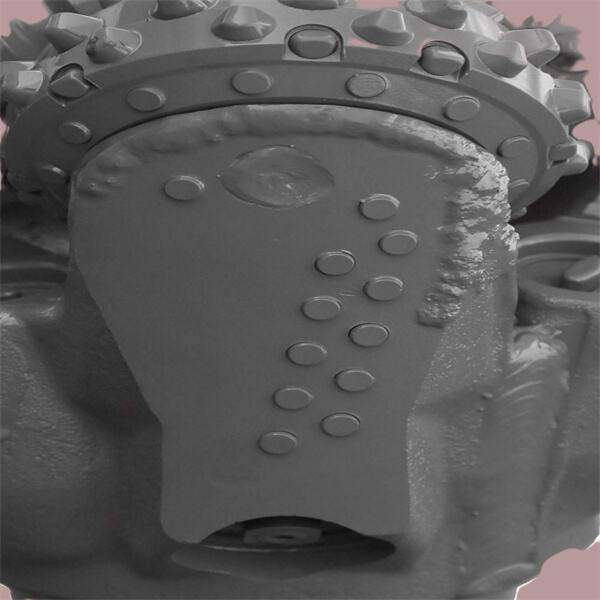

रोलर कोन कटर हो भूमि मा छेद बनाउनको लागि पर्यगत उपकरण। यो एउटा ड्रिल बिट सँग जसले घुमाउँदै हार्ड रॉकहरूमा पनि फस्ती बिच्छ भइरहेको छ। यी कटरहरू कोन क्रशरहरू हुन्, जसले ड्रिल उपकरणको नाम दिन्छ। कोन क्रशरहरूको बाहिरी सतह पूर्णतया रॉकहरूसँग कवर भएको छ र त्यसमा छोटो दाँतहरूसँग सम्पन्न एक शंकु रॉकर छ। यसले रॉकमा ड्रिल बिट घुमाएर छेद बनाउन आरम्भ गर्दछ। यसको महत्व यो हो कि यसले मानिसहरूलाई हाम्रो तलमा रहेका संसाधनहरू (जस्तै फॉसिल फ्यूएल र खनिज) सम्झन पुर्याउँछ।

रोलर कोन कटरहरूले एक बहुत रोबस्ट र विश्वसनीय डिझाइन प्राप्त गर्दछ। डीपफास्ट कोन कटर सेट मजबूत शरीर हुने बाटो सामग्रीहरू जस्तै मेटलको संघटन गरिएको छ; किनभने कटर कठोर पत्थरहरूमा पार गर्दा धेरै दबावहरू पार गर्नुपर्छ। बिटमा राखिएका तीन छोटा कोनहरू त्यो कटरको शरीर बनाउन भइसकेको सामग्रीभन्दा धेरै मजबूत सामग्रीबाट बनाइएका छन्। यदि तिनीहरू भारी उपयोगमा पन्न भएर टूट्छन्, तपाईं नवाँहरू खरीद्न सक्नुहुन्छ किनभने यी कोनहरू प्रतिस्थापन गर्न सकिन्छ। त्यसो भए तिम्रो कोनहरू धेरै समयसम्म तीव्र रहन्छन्, सेगमेन्ट-बिट ठूल्लो बनाएर राख्दछ।

यसलाई सत्य मान्न गर्छौं, तर यसो छैन किनकि रोलर-कोन ड्रिल बिटहरू प्रदुशन बढाउँछन् जसले तेल र गैस को खाताबाट धेरै सामग्री प्राप्त गर्दछ। हाले, रोलर कोन कटर धेरै छोटो छेद बनाउँछ जसले उसको बिटले भूमिको भित्र जान सामग्री बाहिर निकाल्दछ। ठूलो छेदको कारण, धेरै तेल/गैस खाता बाट बाहिर निकालिन सकिन्छ जसले फेरि पनि धेरै सामग्री प्राप्त गर्दछ। यसले सामग्री-भरी संचालनहरू गर्ने व्यवसायहरूलाई आकर्षित गर्दछ। अझै पनि, रोक्कर-कोन बिटहरू जस्तै गहिराइ चट्टानमा प्रवेश गर्ने अन्य कुनै पनि उपकरण छैन।' यसले कम्पनीहरूलाई पहिले अप्राप्य ठाउँहरूमा खोजी गर्न सक्दो छ जसले नयाँ तेल वा गैस क्षेत्रहरू पाउन सक्दो छ।

रोलर कोन कटरलाई अनेक भिन्न स्थितिहरूमा प्रयोग गर्न सकिन्छ किनकि यो बहुतै सुलभ छ। डीपफास्ट कोन कटर लम्बात र क्षैतिज ड्रिलिङ्ग स्थितिहरूमा पनि काम गर्न सक्छ। बस, क्षैतिज ड्रिलिङ्ग धरतीको दिशामा सधैं निचै जान्छ जबकि क्षैतिज कुआ एक कोण रेखामा विभाजित हुन्छ। रोलर कोन कटरलाई योजना अनुसार कुनै पनि निर्दिष्ट कार्यक्रमका आधारमा फरक फरक परियोजनाहरूको आवश्यकतामा लागि डिजाइन गरिएको छ। यसले मालिनो सैलो से दुर्गम ग्रानाइटमाथि पनि ड्रिल गर्न सक्छ। फलस्वरूप, यसको विविध अनुप्रयोगहरूले त्यसलाई तेल र गैस उद्योगको लागि अमूल्य उपकरण बनाएको छ किनभने यसको ड्रिलिङ्ग स्थितिहरूमा थोडाै फरक पनि बढ्दो।

समयको साथ रोलर कोन कटरहरू सुधारिएका छन् तर्कसंगत तकनीकी प्रगतिका कारण। यस कुएहरूलाई नवीन मॉडलहरूमा फैलाएका बढी कोनहरूले बढाउन सकिन्छ र यसैले यो समस्या कम गरिएको छ। डीपफास्ट कोन ड्रिल बिट एक छेदबाट अतिरिक्त संसाधनहरू पुल गर्न तपाईंलाई अनुमति दिन्छ, जसले तेल र गैस कम्पनीहरूले पनि प्रायः पर्याप्त पैसा बचाउने होइन। विशेष गरी, रोलर कोन कटरहरू मोटो कोनहरूसह र उन्नत सेन्सरहरूसह बनाइएका छन्। कटर वा ड्रिलिङ्ग प्रक्रियाले पनिने भित्तिहरूमा सेन्सरले कुनै परिवर्तन देख्न सजिलै हुन्छ भने, यसले यसै बदलहरूलाई पनि प्रभावित गर्दछ। ड्रिलरहरूले यस्तै उपकरणहरू प्रयोग गरेर कुनै पनि समयमा आफ्नो कामहरू सच्याउन सक्छन् भन्ने जान्न उपकरण र उसको बियर दुईवटाइलाई क्षति गर्न बन्द गर्दछ।

सिचुआन डीप फास्ट अयल ड्रिलिंग टुल्स कं., लि.ले जाँच, डिजाइन, उत्पादन, र वितरणसम्मको पूर्ण प्रक्रिया प्रबन्धन प्रणाली प्रदान गर्दछ। डीप फास्टले ग्राहकहरूलाई सम्पूर्ण सहयोग प्रदान गर्न सक्छ। डीप फास्टले उत्तर अमेरिका, दक्षिण अमेरिका, रूसका ग्राहकहरूका लागि रोलर कोन कटर डाउनहोल उपकरणहरू प्रदान गर्दछ। यसले मध्य पूर्व, अफ्रिका, यूके, जापान, दक्षिणपूर्व एसियाका ग्राहकहरूलाई पनि सम्बन्धित सेवाहरू प्रदान गर्दछ। यसको अतिरिक्त, डीप फास्टले ग्राहकहरूका विभिन्न परिस्थितिहरू र समक्ष आएका समस्याहरूको समाधान गर्न अनुकूलित उत्पादनहरू पनि प्रदान गर्न सक्छ। डीप फास्टले सधैं "स्थिरता र ईमानदारी, दृढ़ निश्चय, उपलब्धि" भन्ने मूल मूल्यहरूको पालना गरेको छ र "ड्रिलिंगको आवश्यकताबाट सुरु गरी ग्राहकहरूको सन्तुष्टिसँगै समाप्त गर्ने" लक्ष्य राखेको छ।

डीप फास्टको एकीकृत प्रबंधन प्रणाली ISO 14001 वातावरणीय मानदण्ड, ISO 45001:2018 कार्यस्थलीय स्वास्थ्य र सुरक्षा मानदण्डहरू र API Spec Q1 ISO 9001 (गुणवत्ता) आधारित छ। डीप फास्ट अपना सबै उत्पादन परिक्षण राखिएको छ जसले कच्चा सामग्रीबाट अन्तिम उत्पादनसम्म जान्छ। यस परिक्षणहरूको रोलर कोन कटर्स ग्राहकहरूलाई प्रदान गरिनेछ। डीप फास्टले हाम्रो कर्मचारीहरू र हाम्रो वातावरण सुरक्षित राख्नका लागि प्रबंधन गर्नका लागि प्रक्रिया बिकाश गर्छ। उत्पादन बनाउनका लागि प्रयोग गरिने प्रत्येक प्रक्रिया यी कदमहरू अनुसरण गर्छ।

सिचुआन डीप फास्ट अयल ड्रिलिंग टुल्स को., लि. २००८ मा स्थापित, जसको डाउनहोल टुल्समा ३५ वर्षभन्दा बढीको अनुभव छ, यो चीनको चेंगदुमा अवस्थित छ। डीप फास्टले विभिन्न आकारका पीडीसी बिट्स, विभिन्न संचालन अवस्थामा प्रयोग गरिने डाउनहोल मोटर, र उत्पादनहरूको रखरखावका लागि आवश्यक कुनै पनि कुँदो भागहरू प्रदान गर्दछ। डीप फास्टले जर्मनीको आधुनिक लेथ र जापानको ५-अक्ष एनसीपीसी प्रयोग गरेर प्रतिवर्ष ८००० डायमण्ड बिट्स निर्माण गर्दछ। यो रोलर कोन कटर पेट्रोलियम विश्वविद्यालयसँग दीर्घकालीन योजनामा काम गर्दछ। अहिलेसम्म, ५० पेटेन्टहरू प्राप्त गरिएका छन्, जसमा २ अमेरिकी पेटेन्ट, २ रुसी पेटेन्ट, र ४६ चीनी पेटेन्टहरू समावेश छन्।

डिजाइन मैन्युफैक्चर्सले विश्वभरका तेल र ग्यास कम्पनीहरूद्वारा प्रयोग गरिने डाउनहोल औजारहरूको निर्माण गर्दछ, जसमा रोलर कोन कटर समावेश छ। डीप फास्टले सुरक्षा, दक्षता र विश्वसनीयताका समाधानहरू खोज्ने तेल र ग्यास कम्पनीहरूलाई पेशेवर उपकरणहरू र तकनीशियनहरूको टोलीहरू प्रदान गर्दछ। ग्राहकहरूका सोधपुछहरू र आवश्यकताहरूमा छिटो प्रतिक्रिया र त्वरित जवाफ दिने। सकारात्मक विस्थापन मोटर (PDM) विभिन्न रोटरी स्टियरेबल सिस्टम (RSS) र ऊर्ध्वाधर ड्रिलिङ्ग सिस्टम (VDT) मा अनुकूलित हुन सक्छ। यसको अतिरिक्त, हामी छोटो बिटदेखि बेन्ट PDM सम्मको निर्माण गर्छौं, साथै कुइल्ड ट्यूबिङका लागि PDM पनि उपलब्ध गराउँदछौं। PDC बिटहरू, कोर बिटहरू र बाइ-सेन्टर बिटहरू, इम्प्रेग्नेटेड ड्रिल बिटहरू आदि सजिलै उपलब्ध छन्। ड्रिल बिटहरू विभिन्न आकारमा उपलब्ध छन् र हाम्रा ग्राहकहरूका आवश्यकताहरू पूरा गर्न अनुकूलित गर्न सकिन्छ।