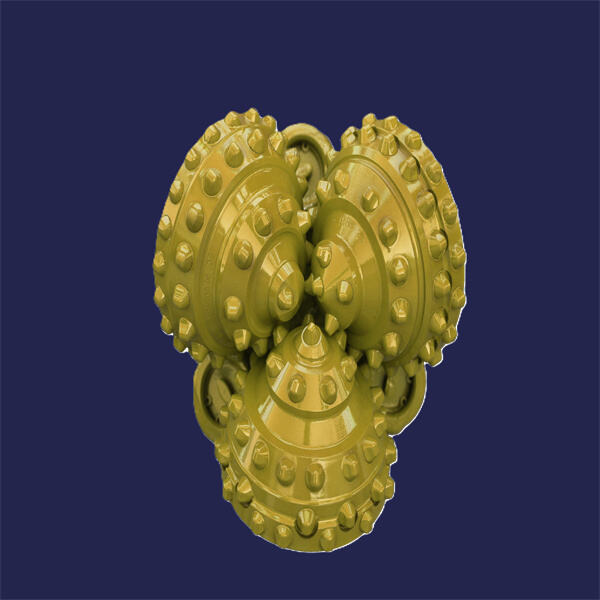

Ever thought about how we go deep down into the earth to get things like oil, gas and precious metals? That is what we call a rotary Tricone rock drill bit. We use it because it allows us to dig holes in the ground so that we can, for example, mine minerals or drill oil and gas wells. It’s amazing when you learn about how this tool functions!

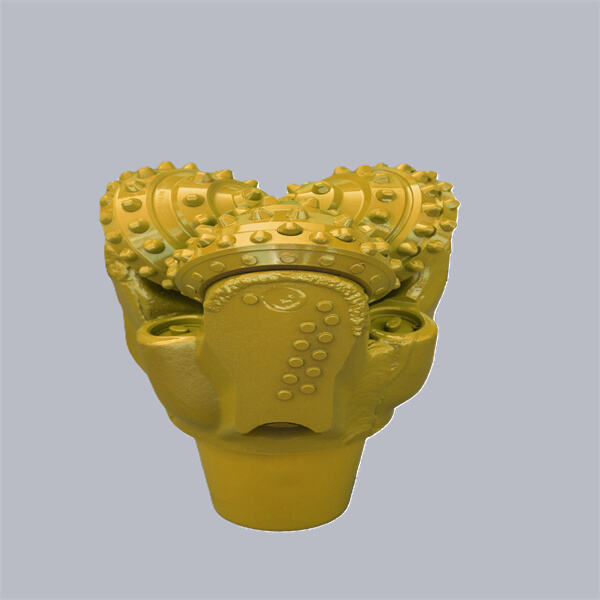

These rotary Tricone bits are very tough drilling tools as they have been tested on some of the hardest rocks. DeepFast rotary drill bit has been made in such a way that it can withstand high pressure and temperature due to which it is capable of drilling deep inside the earth where conditions are very harsh. They are designed in a manner that enables them to work efficiently even in the most difficult drilling situations.

Why would you opt for the use of a rotary Tricone rock drill bit during well-drilling operations? In fact, these are not simple elementary bits at all! They can cut through rock much better than any other type of drill bits produced until now. By being able to do this faster, drilling process will be completed more quickly thus saving time and money.

Prepare yourself for variety with rotary Tricone rocks drills bits; they can bore into different types of rocks! The DeepFast drill bit is able to grind both hard (granite) and soft rocks like clay. Consequently, when mining minerals or extracting oil and gas from kilometers beneath earth's surface, among other many tasks, these stocks become so eminent.

A rotary Tricone rock drill bit works on gravity therefore weight on the bit (WOB) is an important concept here. During drilling into a rock one should load up as many pounds cut as possible and kilometers pumped in order to create overpressure on one bit face that would induce more into rock. Drilling takes longer if the WOB is light and bit life will be shorter than normal. But, when it is too heavy, bashing in of rocks occurs resulting in drilling setbacks and all kinds of things.

Rotary Tricone Drill Bits have changed how we tunnel through rocks and now with new formulas to cut through land like butter. DeepFast Tricone drill bit has enabled us to drill faster, deeper than ever before. These advances have offered a gateway to resources that were once beyond man’s reach. The potential for improvement here is tremendous and could mean a lot for mining or energy production.

Rotary Tricone Drill Bits have come a long way over the years; thanks to technology improvements in both design quality, they are only getting better. We also make them today from stronger durable materials not used then. Additionally, engineers are using computer modeling to develop drill bits that can do specific types of drilling jobs today. This means that we are able to drill in smarter and more effective ways than ever before.

Deep Fast Oil Drilling Tools Co., Ltd. offers all kinds of services its clients. From the initial inquiry the design of product, through manufacturing, and finally delivery of product, Deep Fast has a complete management system. Deep Fast supplies downhole equipment related services to clients across North America, South America, Russia, Middle East, Africa, UK, Japan, Southeast Asia. Deep Fast will also modify the product meet Rotary tricone rock drill bit of the customer depending on the particular circumstances that they facing. Deafest has always stuck principles of "Constancy and Integrity, Determination and Achievement" and the goal "Starting at the beginning drilling needs and ending with complete satisfaction by clients".

Sichuan Deep Fast Oil Drilling Tools Co., Ltd. established 2008 has more than 35 years' experience with downhole tools. Based Chengdu, China, Deep Fast can provide PDC Bits of different sizes, Downhole Motor used various operational situations, and spare parts that can be used support tools. Deploy Japan 5-axis NCPC and Germany Modern lathes. Each year, Deep Fast Rotary tricone rock drill bit average of 8000 diamond bits, and a 2000 downhole motor. Work Southwest Petroleum University a long-term project, date, 50 patents which includes 2 American patents, 2 Russian patents,46 Chinese patents were obtained.

Design manufacture downhole tools for the companies the oil and gas industry across globe. Deep Fast deploys professional equipment and technical teams to service the oil and gas industry seeking safe, efficient and secure solutions. Rapid response quick responses to the client's needs concerns. Positive Displacement Motor (PDM) is able to adapt to various Rotary Steerable System (RSS) as well as Vertical Drilling System (VDT). Rotary tricone rock drill bit, they manufacture Short Bit to Bent PDM In addition, PDM for Coiled Cubing is available. PDC Bits Core Bits and Bi-Center Bits, Impregnated Drill Bits, and more. are available. Drill Bits are offered in various sizes and are able to be customized to meet the requirements of our clients.

Deep Fast's Integrated Management System is based ISO 14001:2015's Environmental Standard, ISO 45001:2018 Occupational Health Safety Standards, as well as API Spec Q1 ISO 9001 (Quality). From raw materials products, deep fast will take strictly test measures ensure the quality their products, results tests will be provided to customers. Then, about the HSE, Deep Fast have Rotary tricone rock drill bit system to protect employees and ensure protection of our environment, each manufacturing procedure be governed by these rules, every month hold the safety meetings and internal training, while some important employees will be involved in professional training outside.